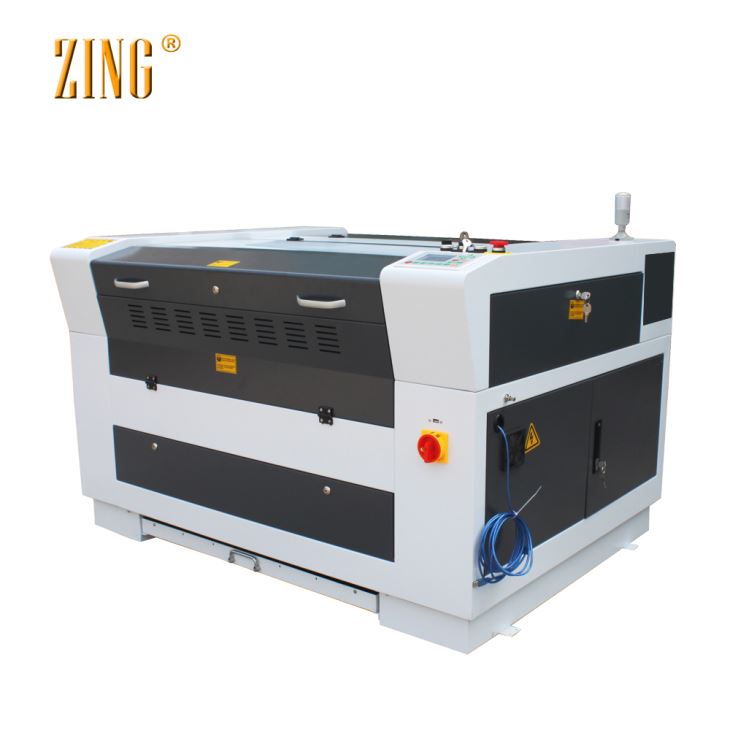

plastic laser cutting machine

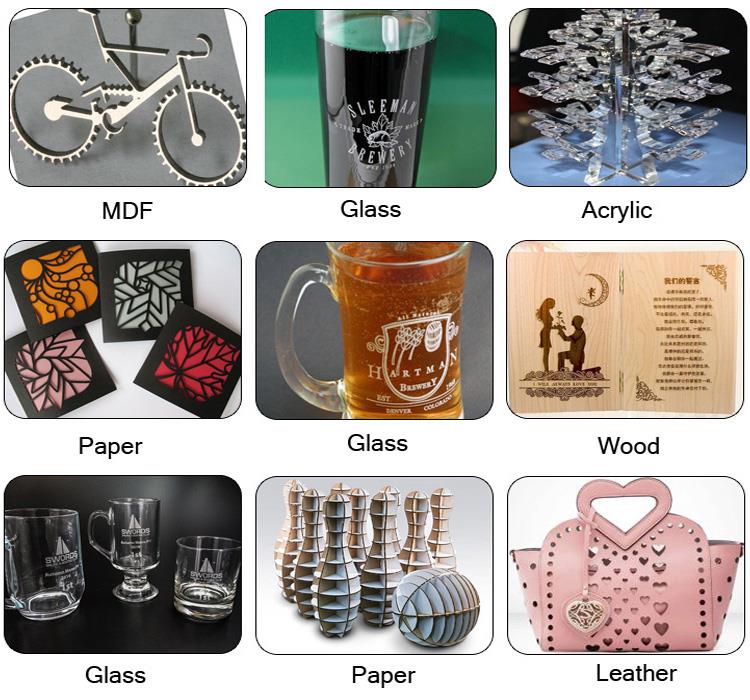

A Pmma Laser Cutting Engraving Machine is a versatile cutting tool that can handle various types of plastics, such as engineering plastics, foam plastics, and common plastics. By directing a high-powered laser beam towards the plastic material, the machine can melt and cut the material with...

Description

A Pmma Laser Cutting Engraving Machine is a versatile cutting tool that can handle various types of plastics, such as engineering plastics, foam plastics, and common plastics. By directing a high-powered laser beam towards the plastic material, the machine can melt and cut the material with pinpoint accuracy. This precision cutting ability allows for the creation of intricate designs and precise cuts, resulting in an ideal plastic product. The laser moves the beam and the plastic product along a predetermined path, which ensures consistency and high-quality results. Whether you're creating intricate shapes or cutting straight lines, a plastic laser cutting machine is an excellent choice for your cutting needs.

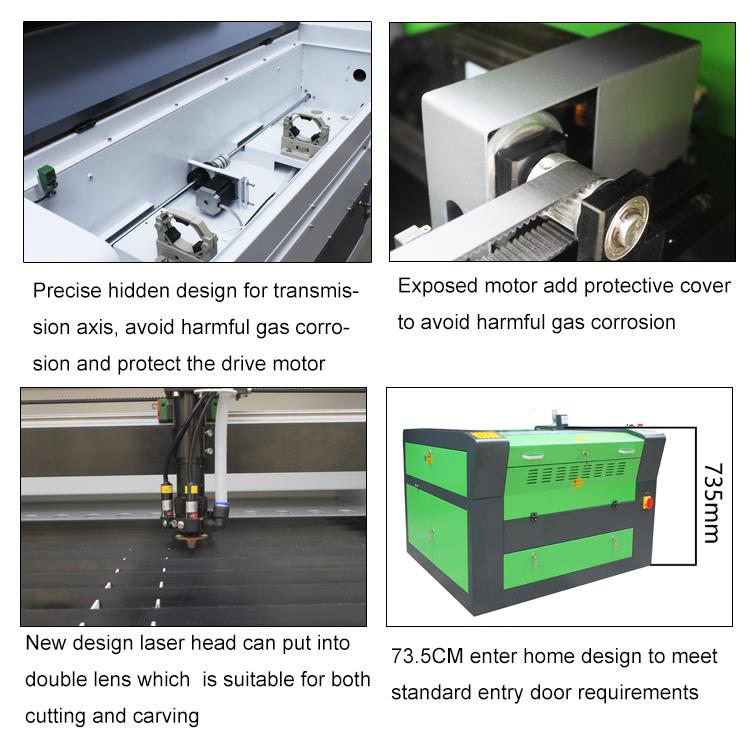

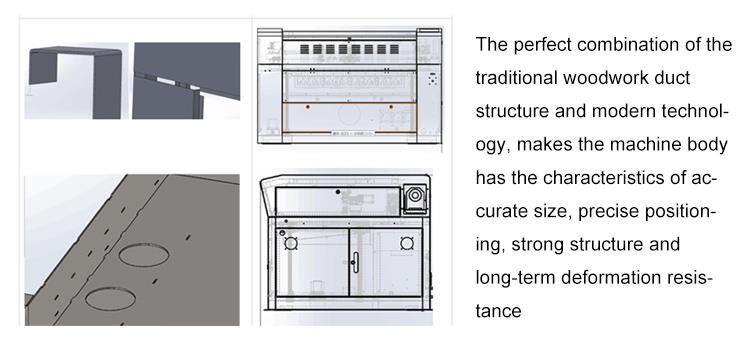

Features:

The Pmma Laser Cutting Engraving Machine is equipped with various impressive features.

Our precision cutting tool offers a range of benefits for your business, including quick processing speeds, ease of use, customizable settings, and pinpoint accuracy. With our laser head trajectory simulation display and optimization functions, you can achieve the best possible results while saving on materials and costs. Our automatic typesetting technology is especially effective for cutting suede and other leather textiles. Discover how our tool can help your business achieve greater efficiency and precision in your cutting process.

The utilization of a PMMA Laser Cutting Engraving Machine facilitates the expeditious development of novel products as it enables immediate laser processing subsequent to the creation of product drawings. Consequently, this allows for the swift acquisition of samples for newly designed plastic items. Thus, this technology greatly reduces the time required for product development.

The standard of the laser cutting is of a high caliber. It doesn't require any contact, so heat has very little impact on the edge, ensuring that there is almost no deformation on the workpiece. This eliminates the possibility of the material collapsing, often a risk with punching dies. Additionally, the cut made by the laser is smooth and even, reducing the need for further processing.

A plastic laser cutting machine offers cost savings on plastic molds by eliminating the need for them. With the plastic laser cutting process, there is no requirement for a mold to be used, no consumption of mold materials, and no need for mold maintenance or replacement. This significantly reduces processing and production costs. The machine is versatile, capable of handling both large and small batches of plastic items or products. By cutting plastic directly, it streamlines the manufacturing process and brings about efficiency and cost-effectiveness.

Technical Parameter: | |||

Product model | Z6040 | Z9060 | Z1390 |

Max working area(mm) | 600x400 | 900x600 | 1300x900 |

Laser power | 60W/80W/100W/120W/150W/180W | ||

Laser Types | Hermetic And Detached CO2 Laser Tube | ||

Engraving speed(mm/min) | 0-75,000 | ||

Cutting speed(mm/min) | 0-40,000 | ||

Minimum letter | English 1 x 1mm | ||

Location precision | ≤0.01mm | ||

Resetting positioning accuracy | 0.01mm | ||

Driving system | Stepper | ||

Software | Lasercut 5.3 or RDworks V8 | ||

360°slope engrave | Yes | ||

Power supply | AC 220V(or 110V)/50~60HZ | ||

Operating temperature | 0 - 45℃ | ||

Operating humidity | 5 - 95% | ||

Laser output control | 1-100% control panel and software setting | ||

Highest scanning precision | 50-1000DPI | ||

Compatible software | CorelDraw, AutoCAD, Photoshop | ||

Auxiliary Devices | Exhaust fan and Exhaust pipe | ||

Cooling mode | Water-cooling and protection system | ||

Operating system | Window 98/ME/2000/XP/VISTA/2007 | ||

Send Inquiry

You Might Also Like