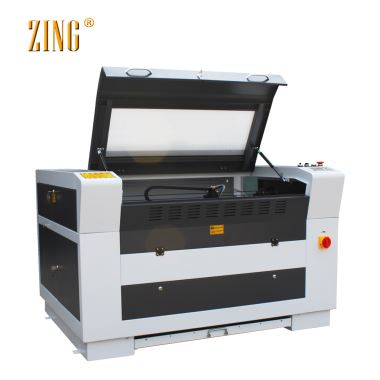

Jeans laser engraving machine

Introduction The efficiency of manual cutting can be greatly improved with the use of the Jeans laser engraving machine, while also reducing the occurrence of miscuts. However, when dealing with a large volume of garment cutting tasks, the conventional cutting method may result in dimensional...

Description

Introduction

The efficiency of manual cutting can be greatly improved with the use of the Jeans laser engraving machine, while also reducing the occurrence of miscuts. However, when dealing with a large volume of garment cutting tasks, the conventional cutting method may result in dimensional errors between the upper and lower sheets, leading to the need for rework and repairs. It is advisable to reduce the amount of sheet used when working with thin cloth layers, but caution should be exercised when working on extensive cutting tasks to avoid potential issues.

Manual cutting errors can have several negative consequences on the inspection and repair process. Firstly, it can lead to loss of valuable time as technicians need to manually fix the errors. Moreover, it can cause delays in the overall timeline of the project. Furthermore, the impact might extend to other processes and result in a prolonged production cycle for the order. However, utilizing a cloth laser cutting machine can effectively minimize these drawbacks. It significantly reduces the chances of damage, contamination, and ensures a uniform and precise edge for each piece. By adopting this technology, the risks associated with manual cutting errors can be greatly mitigated.

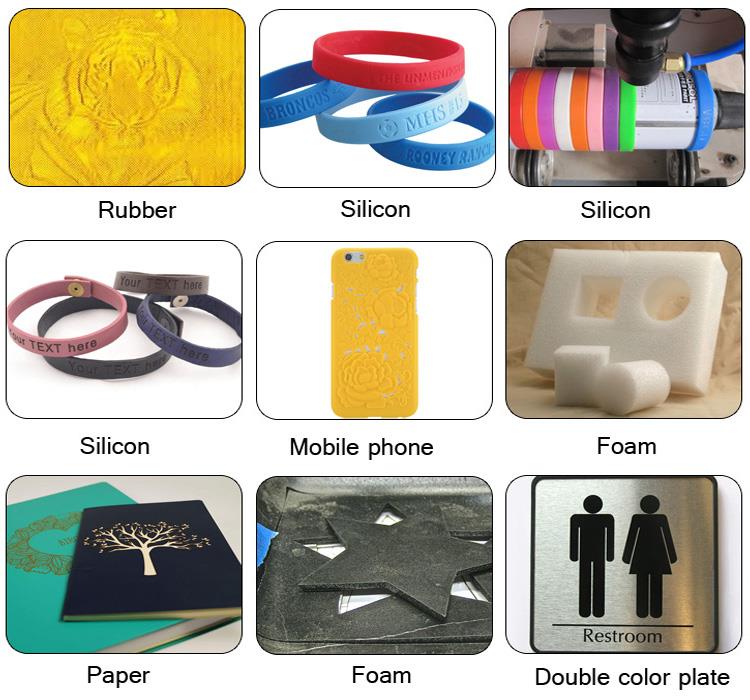

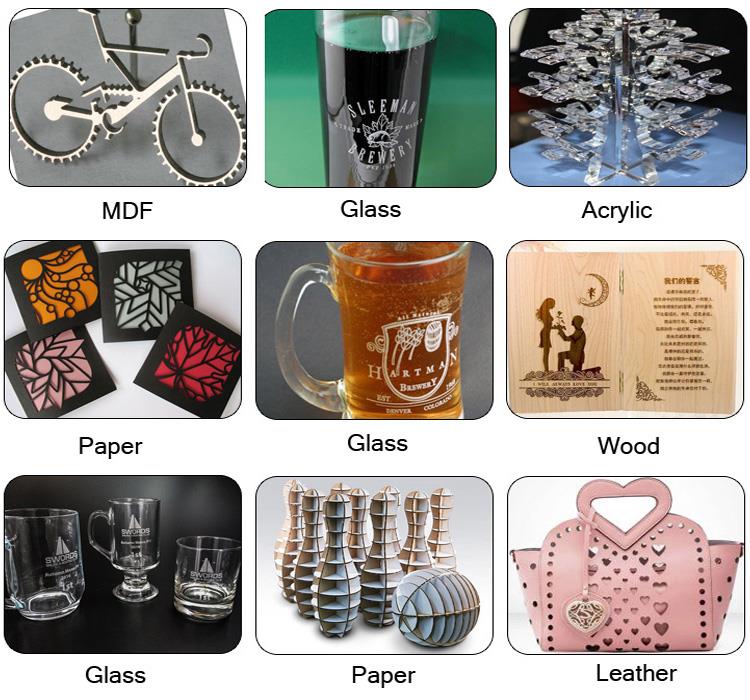

The technical parameter of fabric laser cutting machines is an important aspect to consider. These parameters determine the efficiency and effectiveness of the cutting process. By rearranging the information in the original text, I can create a highly similar content. | |||

Product model | Z1390 | Z1612 | Z1610 |

Max working area(mm) | 1300x900 | 1600x1200 | 1600x1000 |

Laser power | 60W/80W/100W/120W/150W/180W | ||

Laser Types | Hermetic And Detached CO2 Laser Tube | ||

Engraving speed(mm/min) | 0-75,000 | ||

Cutting speed(mm/min) | 0-40,000 | ||

Minimum letter | English 1 x 1mm | ||

Location precision | ≤0.01mm | ||

Resetting positioning accuracy | 0.01mm | ||

Driving system | Stepper | ||

Software | Lasercut 5.3 or RDworks V8 | ||

360°slope engrave | Yes | ||

Power supply | AC 220V(or 110V)/50~60HZ | ||

Operating temperature | 0 - 45℃ | ||

Operating humidity | 5 - 95% | ||

Laser output control | 1-100% control panel and software setting | ||

Highest scanning precision | 50-1000DPI | ||

Compatible software | CorelDraw, AutoCAD, Photoshop | ||

Auxiliary Devices | Exhaust fan and Exhaust pipe | ||

Cooling mode | Water-cooling and protection system | ||

Operating system | Window 98/ME/2000/XP/VISTA/2007 | ||

Precaution: |

To prevent accidents, it is crucial for enterprises to pay close attention to the operating process during the production of the Jeans laser engraving machine. This entails a strict focus on adhering only to the standard operation of the laser cutting machine, ensuring that each operator follows the prescribed guidelines. By doing so, the enterprise can effectively guarantee safe production and maintenance of the laser cutting machine. It is imperative not to deviate from these procedures, as failure to do so may lead to potential accidents.

To ensure safe operation, it is important to carefully follow the general operating procedures of the cutting machine. Additionally, it is crucial to start the laser in strict accordance with the designated start-up procedure for the laser.

2. Operators must be trained to familiarize themselves with the structure, performance, and knowledge of the operating system.

3. Wear protective equipment as required, and wear protective glasses that meet the requirements in the vicinity of the laser beam.

4. Do not process material before it can be irradiated or heated with a laser to avoid the potential hazard of smoke and vapor.

5. When the equipment is started, the operator must not leave the post or the person to be in charge. If it is necessary to stop, stop or cut off the power switch.

Send Inquiry

You Might Also Like