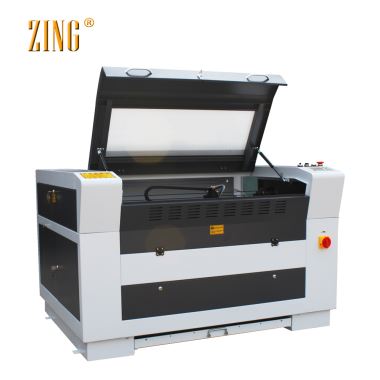

Laser Engraver Cutter 60w 80w 100w 120w 130w 150w

A laser engraver cutter with varying power levels such as 60w, 80w, 100w, 120w, 130w, and 150w showcases impressive attributes including high coherence, strength, and directivity. By utilizing the laser as the source and reflecting it through mirrors, the focused beam is directed onto the...

Description

A laser engraver cutter with varying power levels such as 60w, 80w, 100w, 120w, 130w, and 150w showcases impressive attributes including high coherence, strength, and directivity. By utilizing the laser as the source and reflecting it through mirrors, the focused beam is directed onto the surface of the object being processed. This intense concentration of laser energy rapidly increases the temperature, causing the material to either melt or vaporize swiftly. In conjunction with the movement of the laser head, this process efficiently achieves the desired outcome.

Product model | Z1320 | Z1325 | Z1630 |

Max working area(mm) | 1300x2000 | 1300x2500 | 1600x3000 |

Laser power | 60W/80W/100W/130W/150W/180W | ||

Laser Types | Hermetic And Detached CO2 Laser Tube | ||

Engraving speed(mm/min) | 0-75000 | ||

Cutting speed(mm/min) | 0-40,000 | ||

Minimum letter | English 1 x 1mm | ||

Location precision | ≤0.01mm | ||

Resetting positioning accuracy | 0.01mm | ||

Driving system | Stepper | ||

Software | RD works V8 | ||

360°slope engrave | Yes | ||

Power supply | AC 220V(or 110V)/50~60HZ | ||

Operating temperature | 0 - 45℃ | ||

Operating humidity | 5 - 95% | ||

Laser output control | 1-100% control panel and software setting | ||

Highest scanning precision | 50-1000DPI | ||

Compatible software | CorelDraw, AutoCAD, Photoshop | ||

Auxiliary Devices | Exhaust fan and Exhaust pipe | ||

Cooling mode | Water-cooling and protection system | ||

The effectiveness of an engraving machine is primarily determined by three factors: the engraving speed, engraving intensity, and spot size. When it comes to engraving speed, it refers to the rate at which the laser head moves, typically given in meters per second, leading to greater productivity. Additionally, speed is used to regulate the depth of the cut. With a set laser intensity, the slower the speed, the deeper the cut or engraving. You can modify the speed either through the engraver panel or the computer's print driver.

Features

2. With our advanced Laser Machine Software, you have complete control over the cutting and engraving process of your project. This powerful tool allows you to adjust speed, power, and resolution to achieve the desired results. Plus, you can even engrave vector and picture files directly with ease.

This software offers compatibility with a wide range of design programs and supports various file formats. It can seamlessly integrate with popular software like CorelDraw, PhotoShop, AutoCAD, TAJIMA, Artcut, and more. You can import and work with files in BMP, PLT, DST, DXF, AI, JPG, GIF, PNG, and TIF formats without any hassle. With this extensive compatibility, you have the flexibility to work with your preferred design programs and file types effortlessly.

Software, operation, and installation manuals for laser machines are essential for the proper functioning and utilization of these advanced devices. These comprehensive instructions provide users with all the necessary information and guidance to effectively operate and maintain the laser machine.

The software manual serves as a guide for understanding and operating the software that controls the laser machine. It provides step-by-step instructions on how to install and configure the software, as well as how to use its various features and functions. This manual also includes troubleshooting tips and techniques to resolve any software-related issues.

The operation manual, on the other hand, focuses on the practical aspects of using the laser machine. It covers topics such as machine setup, safety precautions, and operational procedures. This manual provides users with detailed instructions on how to handle the laser machine, adjust settings, and perform various tasks like cutting, engraving, or marking. It also highlights the recommended maintenance and cleaning routines to ensure the machine's longevity and optimum performance.

Lastly, the installation manual provides guidance on setting up the laser machine itself. It contains detailed instructions on how to assemble and install the various components, including the laser source, lens system, control panel, and supporting hardware. This manual also includes information on the machine's power requirements and how to properly connect it to the appropriate power source. Following the installation manual guarantees that the laser machine is correctly set up and ready for operation.

In conclusion, laser machine software, operation, and installation manuals play a vital role in assisting users with the efficient and safe use of these cutting-edge devices. Their comprehensive instructions enable users to maximize the machine's capabilities while ensuring its proper functionality and longevity.

We offer our customers round-the-clock technical assistance, available through various channels such as phone, Skype, or email. Our qualified technicians are always ready to provide you with the help you need, no matter the nature or complexity of the issue. Rest assured that we are dedicated to delivering the unlimited support that you require.

We offer free training sessions on equipment operation and maintenance. Our Technical Support Engineer can assist you either in person at our premises or remotely via phone or Skype. You can rest assured that our expert team will provide you with the necessary knowledge and skills to operate and maintain your equipment effectively.

A maintenance kit that includes tools for both preventive and corrective maintenance is essential for keeping equipment running smoothly. This kit should be well-stocked with all the necessary tools to ensure that both preventive and corrective actions can be taken swiftly. Having a comprehensive kit on hand eliminates the need for technicians to search for tools and parts, which can lead to a longer downtime period. With a thoroughly stocked kit, maintenance tasks can be easily completed in a timely and efficient manner, reducing equipment downtime and minimizing the risk of costly repairs. So, it's crucial to have a well-prepared tool kit for all preventive and corrective maintenance tasks.

Our product comes with a warranty of one year for electronic and mechanical components, while the laser tube and consumables are covered for three months. In case you opt for a Reci tube, we offer a warranty of ten months. This ensures that your investment is protected for a substantial period, so you can use your laser equipment with peace of mind.

7. Guidance & support with our Technical Support Engineers on the installation and setup of your machine.

Packaging and Shipping:

1)Packaging: Whole film packaging machine; anti-collision package edge; fumigation-free plywood wooden box and pallets with iron binding belt. 2)Shipping: We cooperate with shipping company whose experience in the ocean transportation will guarantee your machine safety.

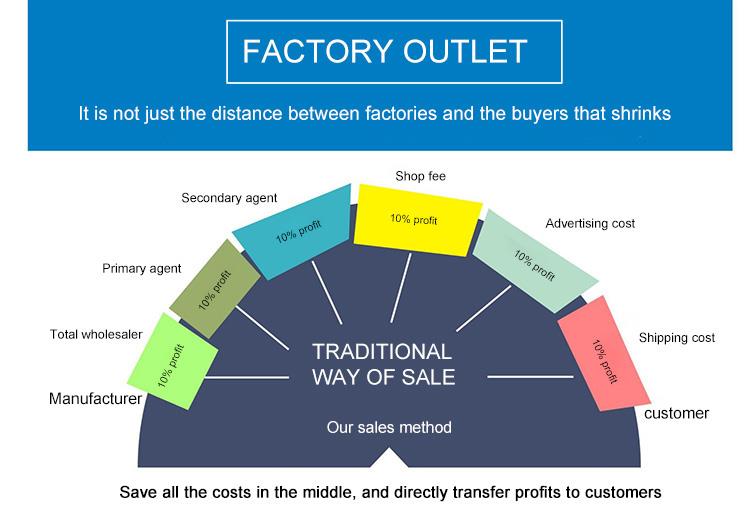

COMPANY INTRODUCTION

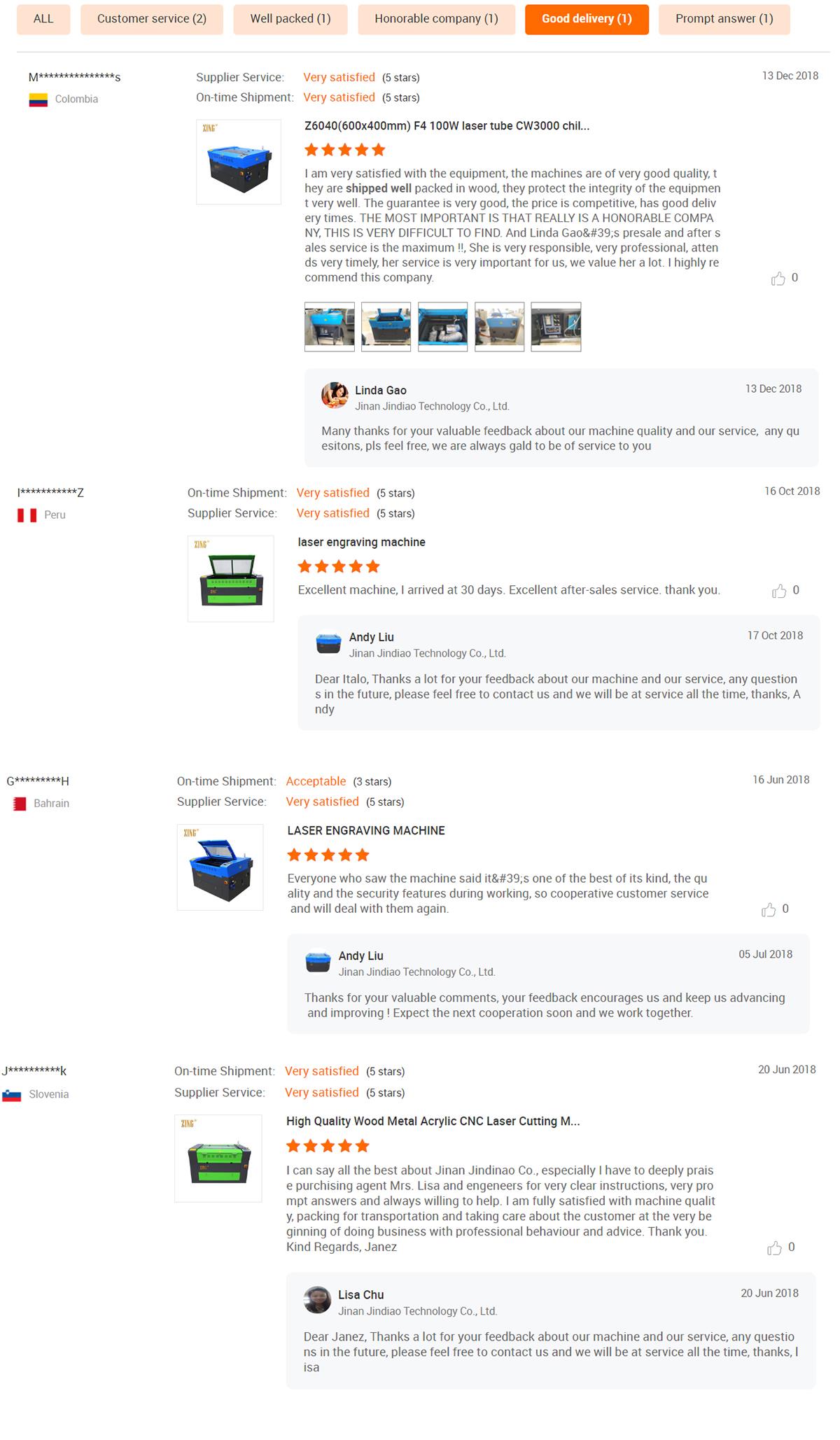

5 STAR HIGH PRAISE

Color is optional and can be customized

Please contact us if you have other special requirements

More machines work video

LEARN MORE

Hot Tags: laser engraver cutter 60w 80w 100w 120w 130w 150w, China laser engraver cutter 60w 80w 100w 120w 130w 150w suppliers, manufacturers, factory

Send Inquiry

You Might Also Like