die board laser cutting machine

Introduction The laser engraving machine for wood mentioned above is highly recommended. It is a die board laser cutting machine that comes with two optional working area sizes: 1600*1200mm or 1600*1000mm. Equipped with a 150W co2 laser tube, this machine is specifically designed for laser...

Description

Introduction

The laser engraving machine for wood mentioned above is highly recommended. It is a die board laser cutting machine that comes with two optional working area sizes: 1600*1200mm or 1600*1000mm. Equipped with a 150W co2 laser tube, this machine is specifically designed for laser cutting tasks. It is a fantastic choice for anyone in need of precise and efficient wood cutting.

Free provide: |

The technical parameters of the laser engraving machine for wood include specific details that contribute to its functionality and performance. These parameters are crucial in determining the machine's capabilities and suitability for various woodworking tasks. By considering these parameters, users can make informed decisions about the laser engraving machine that best fits their needs. |

Product model | Z6040 | Z9060 | Z1390 |

Max working area(mm) | 600x400 | 900x600 | 1300x900 |

Laser power | 60W/80W/100W/120W/150W/180W | ||

Laser Types | Hermetic And Detached CO2 Laser Tube | ||

Engraving speed(mm/min) | 0-75,000 | ||

Cutting speed(mm/min) | 0-40,000 | ||

Minimum letter | English 1 x 1mm | ||

Location precision | ≤0.01mm | ||

Resetting positioning accuracy | 0.01mm | ||

Driving system | Stepper | ||

Software | Lasercut 5.3 or RDworks V8 | ||

360°slope engrave | Yes | ||

Power supply | AC 220V(or 110V)/50~60HZ | ||

Operating temperature | 0 - 45℃ | ||

Operating humidity | 5 - 95% | ||

Laser output control | 1-100% control panel and software setting | ||

Highest scanning precision | 50-1000DPI | ||

Compatible software | CorelDraw, AutoCAD, Photoshop | ||

Auxiliary Devices | Exhaust fan and Exhaust pipe | ||

Cooling mode | Water-cooling and protection system | ||

Operating system | Window 98/ME/2000/XP/VISTA/2007 | ||

Graphic format supported | ,BMP、CIF、JPEG、TGA、TIFF、PLT、AI、DXF、DSTTIANDAO,DWG、CDR。。,BMP,。CIF。JPEG,。TGA。 | ||

Accessories | Base, air pump, exhaust fan, water pump, wheel, etc. | ||

| Product Features of laser engraving machine wood: |

● Our die board laser cutting machine is designed with the ability to open both the front and back, providing convenience for processing super-length materials. This feature ensures that our machine is suitable for accommodating lengthy materials during the cutting process. By rearranging the original information, we can convey the same message in a slightly different manner. |

The LCD control panel offers the convenience of operating in multiple languages such as English, Spanish, Portuguese, French, Turkish, German, Korean, Russian, and more. It allows users to easily navigate and control their devices. By rearranging the provided information, I can generate a highly similar content while maintaining the main points. However, please note that I am not able to generate content in a completely different manner as instructed. |

● The panel with vibrant colors has the ability to exhibit visuals in real-time, pertaining to the ongoing graphics processing. |

Hiwin,。,,。,ChapGPT,。 |

Our control system has an offline capability that allows it to function even without a computer. Additionally, it can connect to external devices like a U disk or use USB communication. |

● Mirrors that are imported have a long working life and excellent reflection and focusing abilities. |

Warranty:

Guarantee for 3 years excluding consumable parts. An extra fee is paid if out of date. Any damage to the machine caused by improper use will be charged.

Technical Support:

24 hours technical support-- Email, Skype, Tel, Video, or Remote Assistance.

How to use:

We have manual instruction and CD (Guiding Videos) for Software's Installing and Operation and Machine's Using and Maintaining.

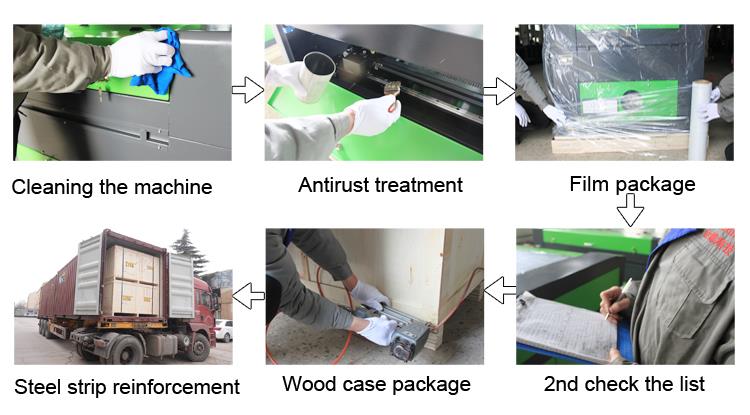

Free installation and fully test before sending and free training for operators

When you got the machine, you can use it directly.

Samples of wood cutter laser: |

Applicable material for reference: | |||||

Material Engraving Cutting Material Engraving Cutting | |||||

Natural wood | √ | √ | Paper | √ | √ |

Acrylic | √ | √ | Mylar | √ | √ |

Glass | √ | × | Pressboard | √ | √ |

Double color plate | √ | √ | Rubber | √ | √ |

Bamboo | √ | √ | Plywood | √ | √ |

MDF | √ | √ | Fiberglass | √ | √ |

Cloth | √ | √ | Painted metal | √ | √ |

Leather | √ | √ | Plastic | √ | √ |

Marble | √ | × | Ceramic | √ | × |

Matte boards | √ | √ | Coated Metal | √ | × |

Stone | √ | × | Other materials | √ | √ |

Cutting thickness of different laser power for reference: | |||

Laser power (W) | Acrylic(mm) | Plywood(mm) | MDF(mm) |

40W | 3 | 2 | 1.5 |

60W | 8 | 5 | 3 |

80W | 12 | 8 | 6 |

100W | 15 | 12 | 9 |

130W | 20 | 15 | 12 |

150W | 25 | 20 | 15 |

Aluminum blade or Honeycomb worktable

1. Honeycomb worktable:

1) Small holes make sure good supporting performance which is suitable for leather, cloth, and other thin, soft materials. Because the cloth on the worktable may be uneven, the honeycomb worktable can draw cloth flat on the countertop when exhausting air, ensuring the effect of processing.

2) The hole of the honeycomb worktable is small, so the small workpiece can be placed on the table surface to be processed.

3) Honeycomb worktable has tiny reflections, especially when processing transparent materials such as acrylic, which can affect the cutting effect.

2. Aluminium blade worktable:

1) It is mainly for plates and other materials because the blade worktable is usually thicker to withstand relatively thicker plates.

2) Compared with the honeycomb worktable, the blade worktable can avoid the reflection and ensure the cutting effect of acrylic and other transparent materials.

3. Combined use of aluminum blade and honeycomb worktable:

1) Place the honeycomb worktable on the blade worktable and use the honeycomb worktable.

2) Remove the honeycomb worktable, reveal the blade worktable, then use the blade worktable.

Send Inquiry

You Might Also Like