flatbed laser cutting machine

Laser cutting has reached an advanced stage with the integration of cutting-edge laser technology and CNC technology. This combination showcases the highest level of precision and effectiveness in laser cutting processes. By utilizing the control system and computer operation, the professional...

Description

Technical Parameter: |

Product model | Z6040 | Z9060 |

Max working area(mm) | 600x400 | 900x600 |

Laser power | 60W/80W/100W/120W/150W/180W | |

Laser Types | Hermetic And Detached CO2 Laser Tube | |

Engraving speed(mm/min) | 0-75,000 | |

Cutting speed(mm/min) | 0-40,000 | |

Minimum letter | English 1 x 1mm | |

Location precision | ≤0.01mm | |

Resetting positioning accuracy | 0.01mm | |

Driving system | Stepper | |

Software | Lasercut 5.3 or RDworks V8 | |

360°slope engrave | Yes | |

Power supply | AC 220V(or 110V)/50~60HZ | |

Operating temperature | 0 - 45℃ | |

Operating humidity | 5 - 95% | |

Laser output control | 1-100% control panel and software setting | |

Highest scanning precision | 50-1000DPI | |

Compatible software | CorelDraw, AutoCAD, Photoshop | |

Product Features: |

Laser cutting has reached an advanced stage with the integration of cutting-edge laser technology and CNC technology. This combination showcases the highest level of precision and effectiveness in laser cutting processes.

By utilizing the control system and computer operation, the professional flatbed laser cutting machine guarantees the utmost cutting quality, while simultaneously enhancing convenience and simplifying the overall operation process.

Due to its rigid gantry structure and high-strength aluminum alloy beam, the machine possesses exceptional durability, allowing it to endure high speeds and accelerations without any compromise.

Utilizing superior technology, the fiber laser cutting machine features a fully integrated imported servo system drive and transmission system. The linear guide, in combination with these advanced systems, ensures that the equipment delivers high-speed, high-precision, and reliable performance.

To ensure the accuracy of machine tool movement, a complete sealing protection system is utilized in the guide rail. This technology prevents oil-free friction motion and dust accumulation, which ultimately improves the lifecycle of transmission components. As a result, the machine tool is well-maintained and performs efficiently without any potential damage from wear and tear.

To ensure stable cutting quality, the cutting head is fitted with an imported non-contact height tracking system powered by a capacitor. This sensitive and accurate system effectively prevents any collision between the cutting head and the processing plate, thus guaranteeing the proper cutting focus position.

The efficiency of production is significantly enhanced through the automated swapping of countertops.

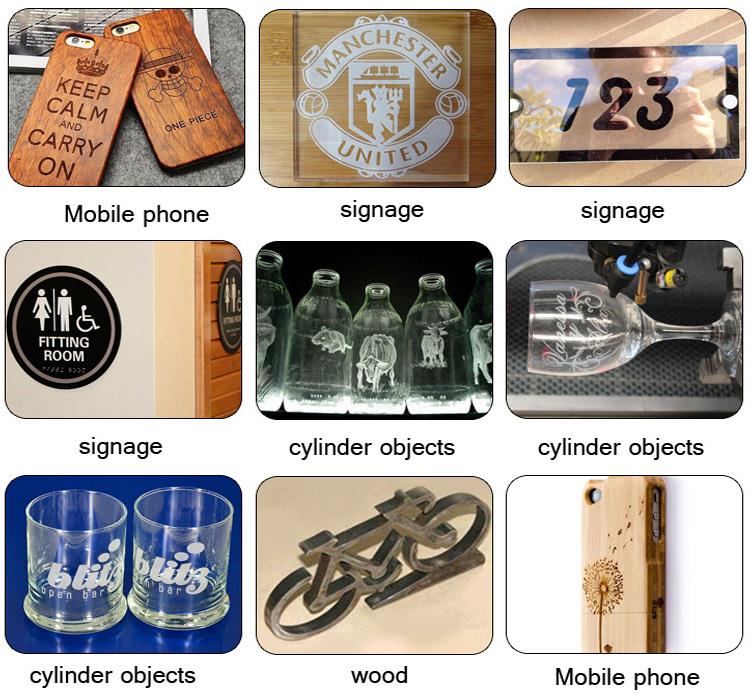

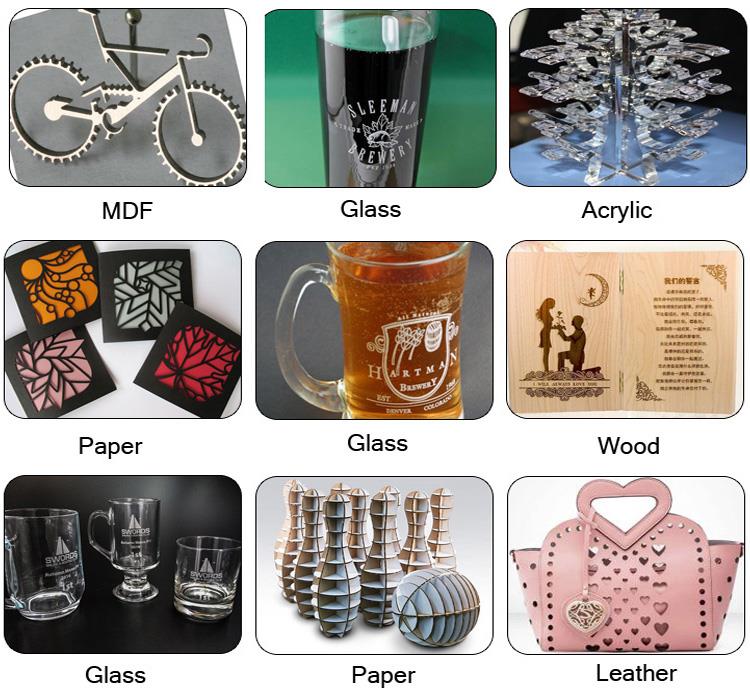

Application field

The use of laser cutting technology is widespread in various industries such as advertising, clothing, surface materials, leather shoes, decoration and furniture, model making, and handicrafts. It is a versatile tool for fine engraving, cutting, and hollowing out of non-metallic materials like acrylic, wood, bamboo, double-color board, glass, paper, and more. With laser cutting, it is possible to create a variety of graphics, characters, images, trademarks, and other decorative elements with ease and precision. Whether it is for commercial or artistic purposes, laser cutting has become an indispensable tool for many industries, and its applications continue to grow.

4. Service of JD laser engraving cutting machine:

1. warranty for 3 years.

2. Maintenance for whole life.

3. We will provide the consumable parts at an agency price.

4. 24 hours online service, free technical support.

5. Machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, pls kindly tell me.

6.We have manual instruction and CD (Guiding Videos) for software Installation, operation and machine's using and maintenance

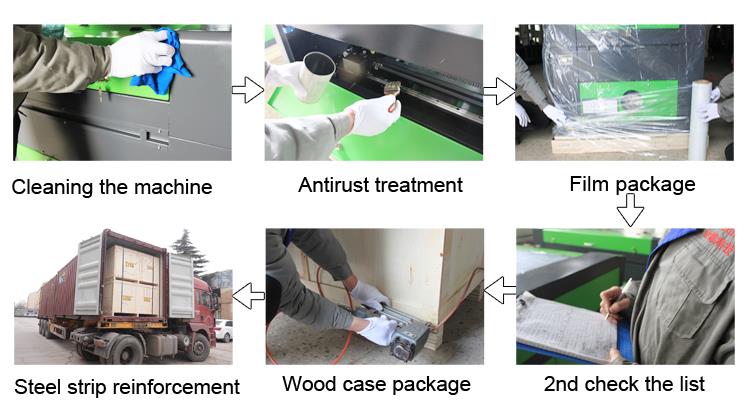

5. Packaging & Shipping

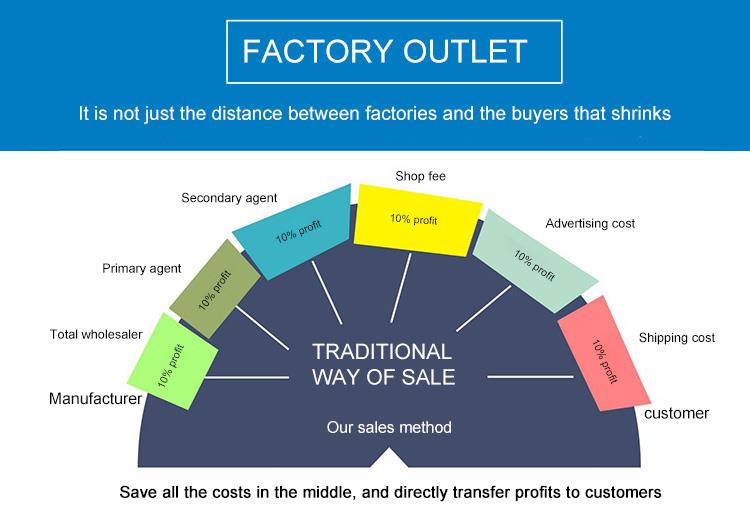

7. Company Information

· Founded in 2002.

· Has developed to a Large-scale International Manufacturing company.

· More Accuracy,More Automatically and Higher Quality Products with Intimate After-sales Service

· Jindiao Be The Leader Of Laser Industry

· Earn the Best Reputation and World-wide Trusted Customers.

· Jindiao laser machines cover all Chinese market and also very popular in America,West Europe,South Asian,East Asian etc. More Than 150 Countries

6. FAQ of laser engraving cutting machine:

Q1: I knew nothing about this machine, what kind of machine i should choose? Very easy to choose. Just tell us what you want to do by using CNC laser machine, then let us give you perfect solutions and suggestions.Q2: When I got this machine, but I don’t know how to use it. What should I do? We will send video and English manual with the machine. If you still have some doubts, we can talk by telephone or skype and e-mail.Q3: If some problems happen to this machine during warranty period, what should I do? We will supply free parts during machine warranty period if machine have some problems. While we also supply free life long after-sales service. So any doubts, just let us know, we will give you solutions. Q4: Before sending me an inquiry on our cnc laser, it is better for you to provide me the following information 1)Your metal or non-metal material size. Because in our factory, we have different models according to working area. 2)Your materials. Metal/Acrylic/plywood/MDF? 3)You want to engrave or cut?

If cut, could you tell me your cutting thickness? Because different cutting thickness need different laser tube power and laser power supplier.

Color is optional and can be customized

Please contact us if you have other special requirement

More machines work video

LEARN MORE

Send Inquiry

You Might Also Like