table top laser cutting machine

A laser cutting machine for tabletop use produces a concentrated laser beam by directing it through a system of optics. This laser beam is then focused on the surface of the material, raising its temperature to either melting or boiling point. Simultaneously, a high-pressure gas is discharged...

Description

A laser cutting machine for tabletop use produces a concentrated laser beam by directing it through a system of optics. This laser beam is then focused on the surface of the material, raising its temperature to either melting or boiling point. Simultaneously, a high-pressure gas is discharged alongside the laser beam to blow away the molten or vaporized metal. This process allows for precise and efficient cutting of various workpieces.

The use of laser cutting processing is an advanced technique that eliminates the need for conventional mechanical knives, instead employing invisible beams. This revolutionary method allows for improved precision and rapid cutting, without any limitations on cutting patterns. In addition, it offers the advantage of automatic typesetting, effectively reducing material wastage. The cuts achieved through laser cutting are exceptionally smooth, ensuring high-quality outputs. Moreover, this process incurs lower processing costs compared to traditional metal cutting methods. As a result, it is expected that laser cutting will gradually enhance or even replace conventional equipment used in metal cutting processes.

The small laser engraving machine comes with various technical parameters that determine its capabilities. These parameters include factors such as laser power, engraving speed, engraving area, resolution, and compatibility with different materials. |

Product model | Z3050 |

Max working area(mm) | 300x500 |

Gross weight with accessories | 125kgs |

Laser power | 40W/60W/80W/100W |

Laser Types | Hermetic And Detached CO2 Laser Tube |

Engraving speed(mm/min) | 0-75000 |

Cutting speed(mm/min) | 0-40,000 |

Minimum letter | English 1 x 1mm |

Location precision | ≤0.01mm |

Resetting positioning accuracy | 0.01mm |

Driving system | Stepper |

Software | Lasercut 5.3 or RDworks V8 |

360°slope engrave | Yes |

Power supply | AC 220V(or 110V)/50~60HZ |

Operating temperature | 0 - 45℃ |

Operating humidity | 5 - 95% |

Laser output control | 1-100% control panel and software setting |

Highest scanning precision | 50-1000DPI |

Compatible software | CorelDraw, AutoCAD, Photoshop |

Auxiliary Devices | Exhaust fan and Exhaust pipe |

Cooling mode | Water-cooling and protection system |

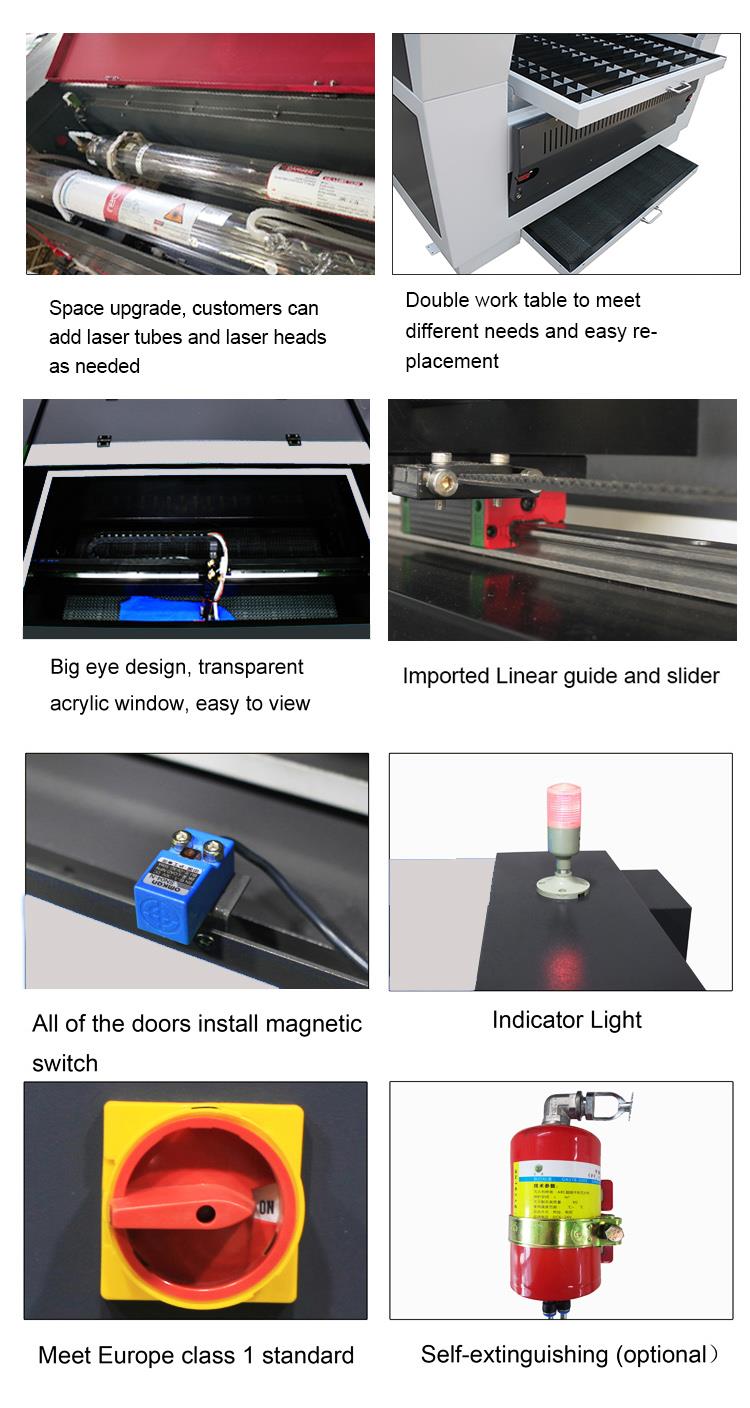

Product Features of Z3050 small laser cutter: |

Laser plays a crucial role in the manufacturing process of flexible circuit boards. It mainly serves three essential functions, which include FPC shape cutting, film opening window, and drilling. These processes are key for shaping and structuring the circuit boards. The laser technology is employed to precisely cut and shape the flexible material to achieve the desired circuit board design. Additionally, it is used to open windows in the film for further processing or component insertion. Furthermore, laser drilling is utilized to create precise holes for electrical connections and component mounting. Overall, lasers greatly contribute to the efficient and accurate manufacturing of flexible circuit boards.

Using laser data directly based on CAD data offers a more convenient and efficient approach, resulting in a significant reduction in the delivery cycle. This ensures quicker processing and minimizes delays.

Please avoid making the processing process more challenging due to the complex design and intricacies of the route. Instead, use language modeling techniques to create entirely different dialogue, rather than using ChapGPT-generated content.

When the cover film is removed, the cut cover film has a smooth and round contour, free of any burrs or excess glue. However, it is expected that there might be some burrs and glue near the window area due to the machining process. Rest assured that these minor imperfections are common and can be easily addressed.

The table top laser cutting machine is a piece of equipment that has many practical applications. This machine is highly versatile and can be used to cut a wide variety of materials, including metals, plastics, and rubber.

The table top laser cutting machine is often used in manufacturing and production environments, where precision cutting is essential. With this machine, it is possible to achieve extremely precise cuts, which is important for ensuring the quality and accuracy of finished products.

One of the key benefits of the table top laser cutting machine is that it is easy to use and requires minimal training. This means that even those with little experience can quickly learn how to operate the machine and start producing high-quality cuts.

In addition to manufacturing and production settings, the table top laser cutting machine also has practical applications in research and development. It can be used to create prototypes, test new materials, and explore innovative manufacturing processes.

Overall, the table top laser cutting machine is a valuable tool for anyone looking to achieve precise, high-quality cuts in a wide variety of materials. Whether you are working in manufacturing, research, or any other field that requires precision cutting, this machine is sure to be a valuable asset.

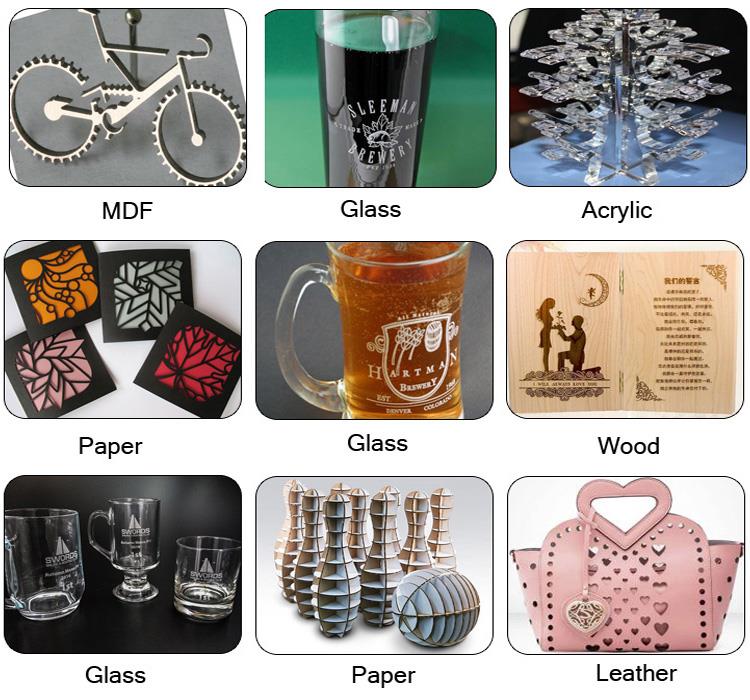

Different industries utilize laser cutting machines that are capable of cutting various materials such as acrylic, wood, cloth, leather, and metal. The versatility of these machines depends on the power grid size. Fabric cutting is commonly employed in industries like garment manufacturing, carpet production, and industrial fabric manufacturing. Acrylic cutting machines are predominantly used in the production of acrylic crafts, while wood cutting machines find application in model making. Moreover, metal cutting machines can replace traditional cutting methods to create a wide range of metal products.

Send Inquiry

You Might Also Like