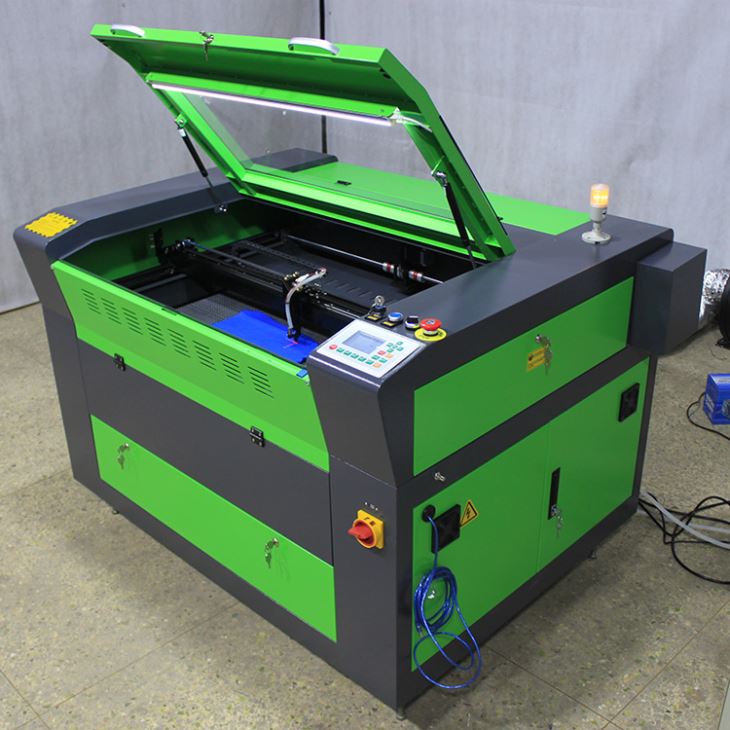

Co2 Laser Engraver Cutter Machine

The Co2 Laser Engraver Cutter Machine utilizes the power of co2 laser technology for precision engraving. This versatile engraving machine is designed with a rear focusing mode, allowing for optimal performance. Despite its compact size, it boasts high integration capabilities, making it...

Description

Technical Parameter: |

Product model | Z1390 | Z1612 |

Max working area(mm) | 1300x900 | 1600x1200 |

Laser power | 60W/80W/100W/120W/150W/180W | |

Laser Types | Hermetic And Detached CO2 Laser Tube | |

Engraving speed(mm/min) | 0-75,000 | |

Cutting speed(mm/min) | 0-40,000 | |

Minimum letter | English 1 x 1mm | |

Location precision | ≤0.01mm | |

Resetting positioning accuracy | 0.01mm | |

Driving system | Stepper | |

Software | Lasercut 5.3 or RDworks V8 | |

360°slope engrave | Yes | |

Power supply | AC 220V(or 110V)/50~60HZ | |

Operating temperature | 0 - 45℃ | |

Operating humidity | 5 - 95% | |

Laser output control | 1-100% control panel and software setting | |

Highest scanning precision | 50-1000DPI | |

Compatible software | CorelDraw, AutoCAD, Photoshop | |

Auxiliary Devices | Exhaust fan and Exhaust pipe | |

Cooling mode | Water-cooling and protection system | |

Operating system | Window 98/ME/2000/XP/VISTA/2007 | |

Product Features: |

The Co2 Laser Engraver Cutter Machine utilizes the power of co2 laser technology for precision engraving. This versatile engraving machine is designed with a rear focusing mode, allowing for optimal performance. Despite its compact size, it boasts high integration capabilities, making it suitable for various applications.

Laser engraving operates on the principle of focusing a laser beam onto the surface of a material using an optical mechanism. The high energy density of the laser beam causes rapid vaporization of the material, resulting in the formation of small pits. A computer-controlled xy console is used to control the movement of the laser head and the switching of the laser as required. The software processes and stores the image information in the computer. To engrave the stored information onto the material, the laser head scans line by line, moving from left to right and top to bottom. As the laser head scans, it turns on when it encounters a "1" point and turns off when it reaches a "0" point. The computer stores the information in binary format, mirroring the two states of the laser switch.

The JD laser engraving cutting machine is known for its exceptional service. It offers a wide range of features and benefits that make it a top choice in the industry. With this machine, users can effortlessly engrave and cut various materials with precision and accuracy. It is designed to meet the needs of professionals and hobbyists alike, ensuring optimal performance and quality results.

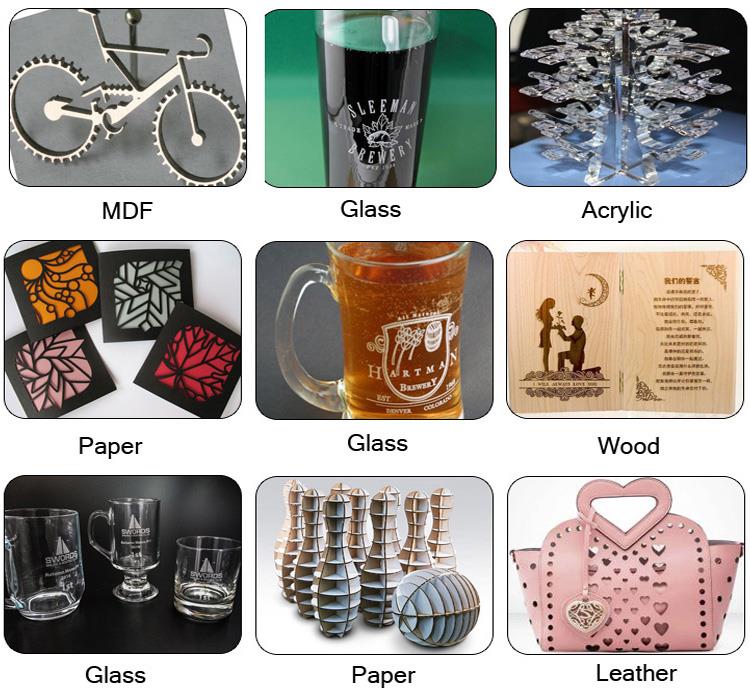

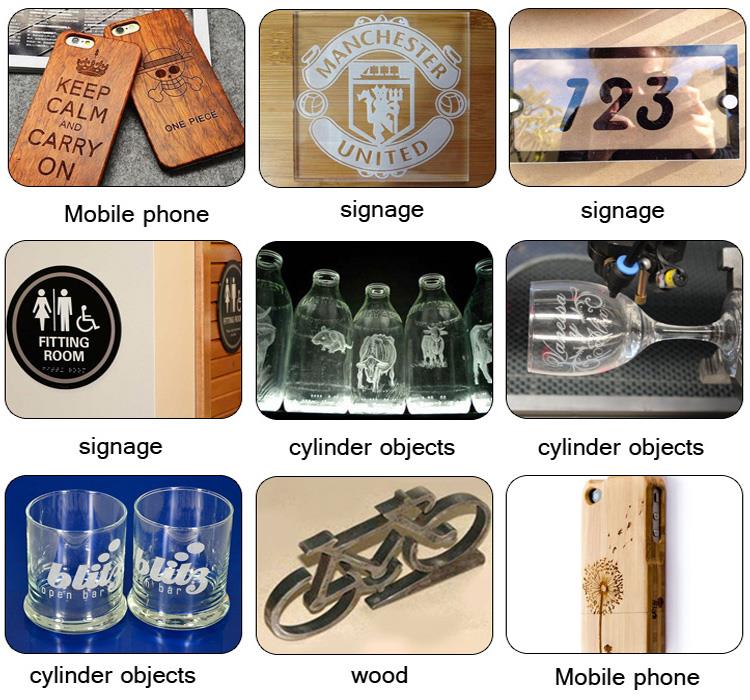

One of the key advantages of the JD laser engraving cutting machine is its versatility. It can handle a diverse range of materials, including wood, acrylic, leather, fabric, and more. This makes it ideal for a variety of applications, from crafting and signage to industrial prototyping and manufacturing.

The machine's cutting-edge technology allows for high-speed engraving and precise cutting. It employs a powerful laser beam that vaporizes or melts the material, creating intricate and detailed designs. The laser beam can be adjusted to different intensities and speeds, giving users full control over the engraving and cutting process.

In addition to its impressive performance, the JD laser engraving cutting machine is also renowned for its user-friendly interface. It features intuitive software that simplifies the design and cutting process. Users can easily import designs, customize settings, and monitor the progress of their projects. The machine also provides comprehensive safety features, ensuring a secure working environment.

Furthermore, the JD laser engraving cutting machine offers reliable and consistent results. It boasts a high level of accuracy, ensuring that every detail is precisely replicated. The machine is built with durable and high-quality components, guaranteeing long-lasting performance and minimal downtime.

Overall, the JD laser engraving cutting machine stands as a reliable and efficient solution for all engraving and cutting needs. Its exceptional service, versatility, cutting-edge technology, user-friendly interface, and reliable results make it a top choice for professionals and hobbyists alike. With this machine, users can unleash their creativity and achieve stunning and precise outcomes.

1. warranty for 3 years.

2. Maintenance for whole life.

At an agency price, the consumable parts will be made available to you. The content provided above can be rearranged to create a similar message while maintaining the original text's information.

We offer free technical support and round-the-clock online customer service. Our team is always available to assist you with any issues you may have.

5. Machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, pls kindly tell me.

6.We have manual instruction and CD (Guiding Videos) for software Installation, operation and machine's using and maintenance

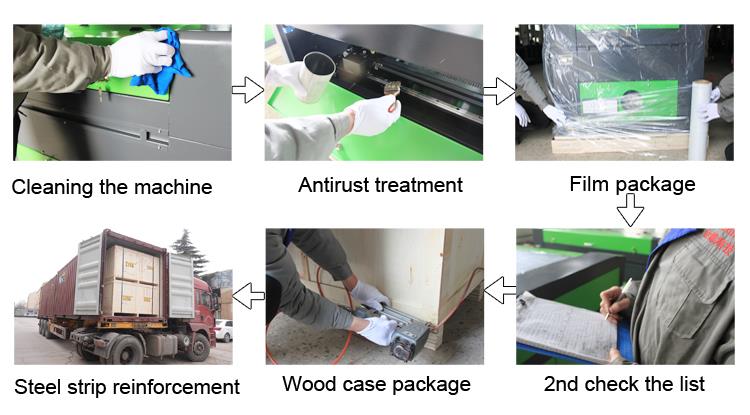

5. Packaging & Shipping

7. Company Information

· Founded in 2002.

· Has developed to a Large-scale International Manufacturing company.

· More Accuracy,More Automatically and Higher Quality Products with Intimate After-sales Service

· Jindiao Be The Leader Of Laser Industry

· Earn the Best Reputation and World-wide Trusted Customers.

· Jindiao laser machines cover all Chinese market and also very popular in America,West Europe,South Asian,East Asian etc. More Than 150 Countries

6. FAQ of laser engraving cutting machine:

Q1: I knew nothing about this machine, what kind of machine i should choose? Very easy to choose. Just tell us what you want to do by using CNC laser machine, then let us give you perfect solutions and suggestions.Q2: When I got this machine, but I don’t know how to use it. What should I do? We will send video and English manual with the machine. If you still have some doubts, we can talk by telephone or skype and e-mail.Q3: If some problems happen to this machine during warranty period, what should I do? We will supply free parts during machine warranty period if machine have some problems. While we also supply free life long after-sales service. So any doubts, just let us know, we will give you solutions. Q4: Before sending me an inquiry on our cnc laser, it is better for you to provide me the following information 1)Your metal or non-metal material size. Because in our factory, we have different models according to working area. 2)Your materials. Metal/Acrylic/plywood/MDF? 3)You want to engrave or cut?

If cut, could you tell me your cutting thickness? Because different cutting thickness need different laser tube power and laser power supplier.

Color is optional and can be customized

Please contact us if you have other special requirement

Send Inquiry

You Might Also Like