CNC Laser Engraving Cutting Machine

The CNC Laser Engraving Cutting Machine is specifically designed to ensure exceptional speed and stability during the laser cutting process. Equipped with powerful fiber lasers, it enables high-speed and precision machining of various metals and materials. Thanks to its dynamic focusing device,...

Description

Technical Parameter: |

Product model | Z6040 | Z9060 | Z1390 |

Max working area(mm) | 600x400 | 900x600 | 1300x900 |

Laser power | 60W/80W/100W/120W/150W/180W | ||

Laser Types | Hermetic And Detached CO2 Laser Tube | ||

Engraving speed(mm/min) | 0-75,000 | ||

Cutting speed(mm/min) | 0-40,000 | ||

Minimum letter | English 1 x 1mm | ||

Location precision | ≤0.01mm | ||

Resetting positioning accuracy | 0.01mm | ||

Driving system | Stepper | ||

Software | Lasercut 5.3 or RDworks V8 | ||

360°slope engrave | Yes | ||

Power supply | AC 220V(or 110V)/50~60HZ | ||

Operating temperature | 0 - 45℃ | ||

Operating humidity | 5 - 95% | ||

Laser output control | 1-100% control panel and software setting | ||

Highest scanning precision | 50-1000DPI | ||

Compatible software | CorelDraw, AutoCAD, Photoshop | ||

Product Features: |

The CNC Laser Engraving Cutting Machine is specifically designed to ensure exceptional speed and stability during the laser cutting process. Equipped with powerful fiber lasers, it enables high-speed and precision machining of various metals and materials. Thanks to its dynamic focusing device, it maintains consistent cutting quality for an efficient and cost-effective solution for large-format laser cutting. This cutting-edge machine offers both cutting and punching capabilities, making it a versatile tool for a wide range of applications. Experience the unmatched performance of the CNC Laser Engraving Cutting Machine for your next project.

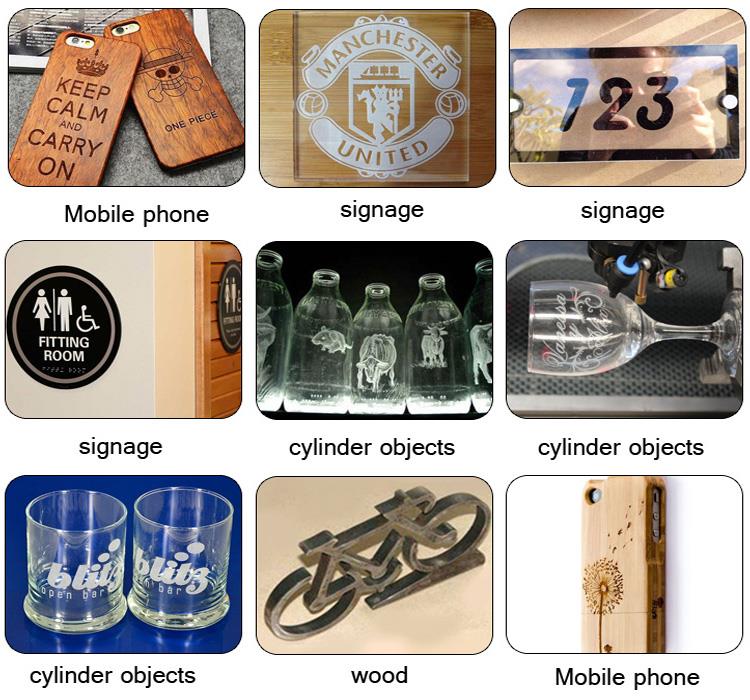

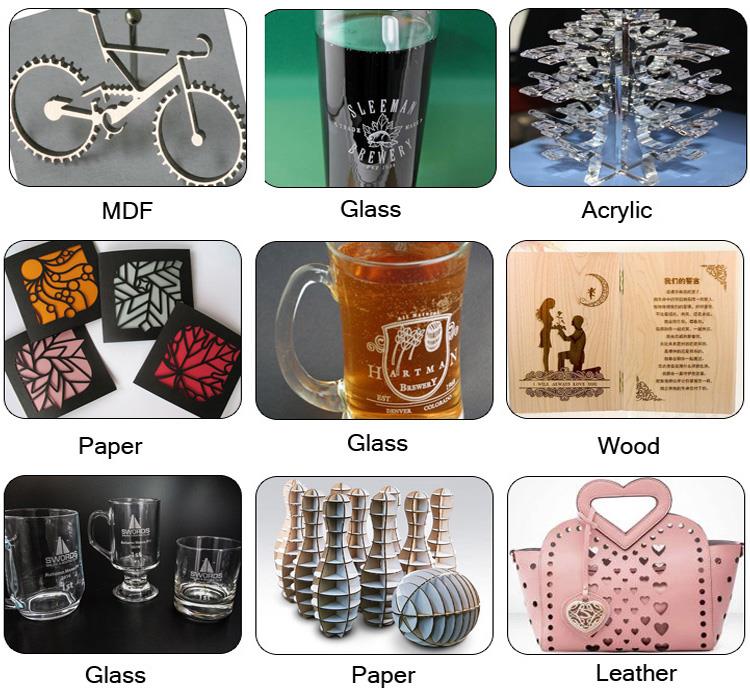

Machinable material

We have a wide range of metal sheet and pipe cutting options available, including stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum and aluminum alloys. In addition, we also work with galvanized sheet, aluminum-zinc plate, pickling plate, and even titanium. Whatever your needs may be, we have the expertise and capability to handle even the most demanding projects. Our team of skilled professionals is dedicated to ensuring that you get the quality results you need, on time and within budget. So why wait? Contact us today to learn more about our metal cutting services and how we can help you achieve your goals.

Applicable industry

The applications of this technology are widespread and versatile, making it an ideal solution for a range of industries, including sheet metal processing, advertising sign production, high and low voltage electrical cabinet production, and mechanical parts manufacturing. It is also commonly used in the production of kitchen utensils, automobiles, machinery, metal crafts, saw blades, electrical parts, and is particularly prevalent in the glasses industry, spring sheets, circuit boards, electric kettles, medical microelectronics, hardware, and knife measuring tools. With such a diverse range of applications, this technology is an essential tool for any industry that requires precision metal cutting and manufacturing.

The JD laser engraving cutting machine offers a range of services. These services ensure precise and efficient engraving and cutting capabilities. By rearranging the content provided above, we can generate a highly similar content based on the original information.

1. Guarantee for 2 years.

2. Maintenance for whole life.

At an agency price, we'll furnish you with all the essential consumable parts you need. You can be certain that our prices are reasonable and will not break the bank.

Our technical support team is available round the clock for 24 hours to assist you with any queries or issues you may face. Our online service is designed to cater to your needs at any time of the day or night, ensuring that you have access to our help whenever you need it. Best of all, our technical support is completely free of charge, so you can rest assured that you won't have to pay a penny for our assistance. Whether you have a question about our products or need help troubleshooting an issue, our team is here to help you every step of the way. So why wait? Contact us today and experience the best technical support in the business!

We have made adjustments to the machine prior to delivery and included an operation disk in the package. If you have any further inquiries, please feel free to let me know.

We provide a range of resources to assist with software installation, operation, and machine maintenance. These include a manual with detailed instructions and a CD containing guiding videos. Whether you need guidance on the installation process or tips on how to effectively operate and maintain your machine, our comprehensive materials have got you covered. By rearranging the given content, we aim to generate a highly similar but creatively rephrased version that reflects the original information.

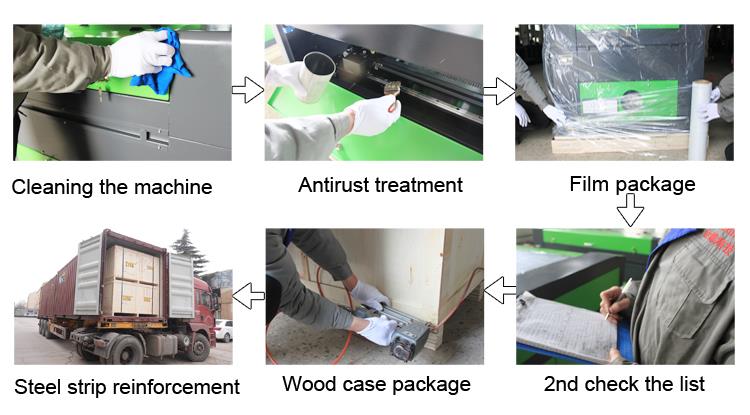

5. Packaging & Shipping

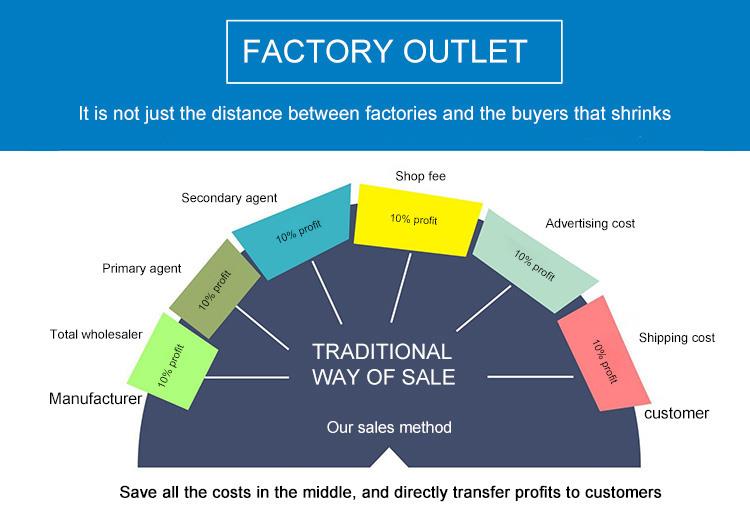

7. Company Information

· Founded in 2002.

· Has developed to a Large-scale International Manufacturing company.

· More Accuracy,More Automatically and Higher Quality Products with Intimate After-sales Service

· Jindiao Be The Leader Of Laser Industry

· Earn the Best Reputation and World-wide Trusted Customers.

· Jindiao laser machines cover all Chinese market and also very popular in America,West Europe,South Asian,East Asian etc. More Than 150 Countries

6. FAQ of laser engraving cutting machine:

Q1: I knew nothing about this machine, what kind of machine i should choose? Very easy to choose. Just tell us what you want to do by using CNC laser machine, then let us give you perfect solutions and suggestions.Q2: When I got this machine, but I don’t know how to use it. What should I do? We will send video and English manual with the machine. If you still have some doubts, we can talk by telephone or skype and e-mail.Q3: If some problems happen to this machine during warranty period, what should I do? We will supply free parts during machine warranty period if machine have some problems. While we also supply free life long after-sales service. So any doubts, just let us know, we will give you solutions. Q4: Before sending me an inquiry on our cnc laser, it is better for you to provide me the following information 1)Your metal or non-metal material size. Because in our factory, we have different models according to working area. 2)Your materials. Metal/Acrylic/plywood/MDF? 3)You want to engrave or cut?

If cut, could you tell me your cutting thickness? Because different cutting thickness need different laser tube power and laser power supplier.

Color is optional and can be customized

Please contact us if you have other special requirements

Send Inquiry

You Might Also Like