cnc laser engraving machine

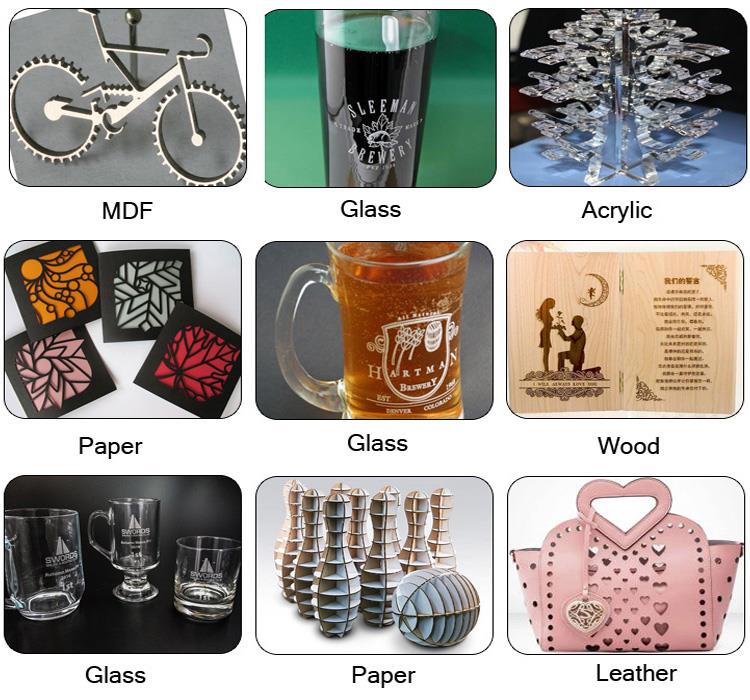

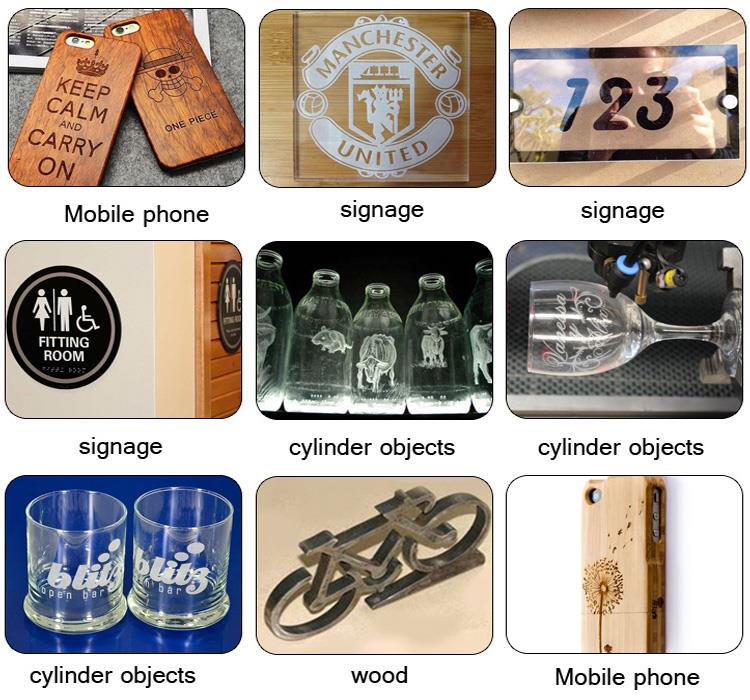

The CNC laser engraving machine is a versatile tool capable of performing a range of carving techniques including relief, flat, and hollow carving. With its high precision and fast engraving speed, it can be used on a variety of materials such as wood, metal, and acrylic, making it ideal for use...

Description

Technical Parameter of cnc machine laser cutting: | |||

Product model | Z1390 | Z1612 | Z1610 |

Max working area(mm) | 1300x900 | 1600x1200 | 1600x1000 |

Laser power | 60W/80W/100W/120W/150W/180W | ||

Laser Types | Hermetic And Detached CO2 Laser Tube | ||

Engraving speed(mm/min) | 0-75,000 | ||

Cutting speed(mm/min) | 0-40,000 | ||

Minimum letter | English 1 x 1mm | ||

Location precision | ≤0.01mm | ||

Resetting positioning accuracy | 0.01mm | ||

Driving system | Stepper | ||

Software | Lasercut 5.3 or RDworks V8 | ||

360°slope engrave | Yes | ||

Power supply | AC 220V(or 110V)/50~60HZ | ||

Operating temperature | 0 - 45℃ | ||

Operating humidity | 5 - 95% | ||

Laser output control | 1-100% control panel and software setting | ||

Highest scanning precision | 50-1000DPI | ||

Compatible software | CorelDraw, AutoCAD, Photoshop | ||

Auxiliary Devices | Exhaust fan and Exhaust pipe | ||

Cooling mode | Water-cooling and protection system | ||

Operating system | Window 98/ME/2000/XP/VISTA/2007 | ||

Product Features of laser machine engraving: |

The CNC laser engraving machine is a versatile tool capable of performing a range of carving techniques including relief, flat, and hollow carving. With its high precision and fast engraving speed, it can be used on a variety of materials such as wood, metal, and acrylic, making it ideal for use in the production of wooden doors, furniture, and other decorative items. Whether you're a professional woodworker or a hobbyist looking to add a personal touch to your creations, the CNC laser engraving machine is a powerful and reliable choice for all your carving needs.

The foundation of a CNC machine is constructed using a robust and sturdy steel pipe, ensuring durability. To create a stable and rigid processing platform, meticulous finite element analysis and design are conducted. Before the machining process begins, all components of the machine bed undergo stress relief to guarantee optimal performance.

To ensure optimal maintenance for CNC engraving machines, it is recommended to utilize a centralized automatic lubrication system for all positioning bearings, ball screws, linear guides, and racks. This approach is endorsed by the manufacturers of these key components. By integrating this lubrication system with the overall machine control system, it becomes easier to administer routine maintenance and extend the lifespan of your CNC engraving machine.

The international top brands are chosen for the main components of CNC woodworking engraving machine models.

The CNC woodworking engraving machine is equipped with a tool magazine that is specially designed to ensure compatibility. The state-of-the-art CNC system controls the tool magazine, enabling the machine to rapidly and accurately change tools. This results in increased efficiency and reliability during the engraving process.

Machine features:

-Sturdy solid metal construction, well balanced

-High precision, high speed laser engraver

This laser engraver boasts a formidable amount of laser engraving power, with several watts to its name.

The ability to adjust power and speed levels is essential for achieving flawless engravings on almost any type of surface.

-Ability to handle various graphic formats such as BMP, HPGL, PLT, DST, DXP, and AI is one of its key features.

Our Services:

| 1. Guarantee for 2 years. |

| 2. Maintenance free of charge for 2 years . |

| 3. We will provide the consumable parts at an agency price. |

| 4. 24 hours online service, free technical support. |

| 5. Machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, pls kindly tell me. |

| 6. We have manual instruction and CD (Guiding Videos) for software Installation, operation and machine's using and maintenance. |

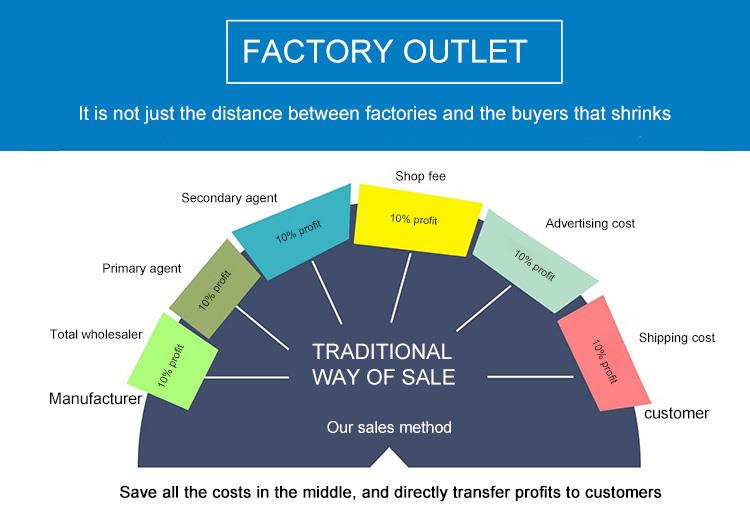

Company Information

Founded in 2002.

Has developed to a Large-scale International Manufacturing company.

More Accuracy,More Automatically and Higher Quality Products with Intimate After-sales Service

Jindiao Be The Leader Of Laser Industry

Earn the Best Reputation and World-wide Trusted Customers.

Jindiao laser machines cover all Chinese market and also very popular in America,West Europe,South Asian,East Asian etc. More Than 80 Countries.

FAQ

Q1: I knew nothing about this machine, what kind of machine i should choose? Very easy to choose. Just tell us what you want to do by using CNC laser machine, then let us give you perfect solutions and suggestions. Q2: When I got this machine, but I don’t know how to use it. What should I do? We will send video and English manual with the machine. If you still have some doubts, we can talk by telephone or skype and e-mail. Q3: If some problems happen to this machine during warranty period, what should I do? We will supply free parts during machine warranty period if machine have some problems. While we also supply free life long after-sales service. So any doubts, just let us know, we will give you solutions. Q4: Before sending me an inquiry on our cnc laser, it is better for you to provide me the following information 1)Your metal or non-metal material size. Because in our factory, we have different models according to working area. 2)Your materials. Metal/Acrylic/plywood/MDF? 3)You want to engrave or cut?

If cut, could you tell me your cutting thickness? Because different cutting thickness need different laser tube power and laser power supplier.

Send Inquiry

You Might Also Like