laser leather cutting machine

The laser leather cutting machine is specifically designed for leather cutting. It features a unique design with lower suction and a split structure, which greatly enhances cutting speed and provides excellent cutting results. The cuts are perfectly flat and do not result in any yellowing of the...

Description

Technical Parameter laser leather cutter: | |||

Product model | Z1320 | Z1325 | Z1630 |

Max working area(mm) | 1300x2000 | 1300x2500 | 1600x3000 |

Laser power | 60W/80W/100W/130W/150W/180W | ||

Laser Types | Hermetic And Detached CO2 Laser Tube | ||

Engraving speed(mm/min) | 0-75000 | ||

Cutting speed(mm/min) | 0-40,000 | ||

Minimum letter | English 1 x 1mm | ||

Location precision | ≤0.01mm | ||

Resetting positioning accuracy | 0.01mm | ||

Driving system | Stepper | ||

Software | Lasercut 5.3 or RDworks V8 | ||

360°slope engrave | Yes | ||

Power supply | AC 220V(or 110V)/50~60HZ | ||

Operating temperature | 0 - 45℃ | ||

Operating humidity | 5 - 95% | ||

Laser output control | 1-100% control panel and software setting | ||

Highest scanning precision | 50-1000DPI | ||

Compatible software | CorelDraw, AutoCAD, Photoshop | ||

Auxiliary Devices | Exhaust fan and Exhaust pipe | ||

Cooling mode | Water-cooling and protection system | ||

Operating system | Window 98/ME/2000/XP/VISTA/2007 | ||

Graphic format supported | There are a variety of file formats that are commonly used in the world of graphic design and embroidery. Some of the most popular file extensions include BMP, CIF, JPEG, TGA, TIFF, PLT, AI, DXF, DST, DWG, and CDR. Whether you're working with vector or raster graphics, there's a file format out there that can help you achieve your design goals. And with modern software tools, it's easier than ever to convert between different file types so that you can work with the formats that suit your needs best. No matter what kind of work you do, having a solid understanding of file formats is essential for success. | ||

Accessories | Water pump, air pump, exhaust fan, base, wheel etc | ||

Product Features: |

The laser leather cutting machine is specifically designed for leather cutting. It features a unique design with lower suction and a split structure, which greatly enhances cutting speed and provides excellent cutting results. The cuts are perfectly flat and do not result in any yellowing of the leather. The machine adopts an advanced X-axis and Y-axis stepping system, equipped with imported linear guides or slides and high-quality stepper motors. The entire machine is constructed from durable stainless steel and manufactured with high precision, ensuring that the machining accuracy error remains within 0-0.5mm. The inclusion of an efficient and stable power switch, as well as USB data transmission, significantly improves the overall stability and performance of the machine. With faster processing speed and higher precision, this laser leather cutting machine guarantees efficient and reliable operation.

The leather laser cutting machine is equipped with an advanced 32-bit high-speed control system that enhances its performance to a great extent. Its action is incredibly smooth and fast thanks to the use of S-type acceleration and deceleration control software. What's more, the machine comes with a light intensity and speed automatic matching function that guarantees the quality of corner cutting. Additionally, it features a continuous curve cutting function that enables users to achieve a maximum cut speed of 36m/m when working on curves.

The leather laser cutting machine utilizes a high-frequency uniform power CO2 laser tube and is equipped with a constant temperature cooling system. This powerful combination ensures that the machine can operate continuously for 24 hours, without any interruptions. As a result, the processing effect on each item remains consistent and reliable.

The high-quality leather laser cutting machine utilizes a non-contact thermal processing technique that guarantees exceptional results. Its remarkable features include a narrow heat diffusion range and precise cutting, leaving no rough edges. With its remarkable versatility, it can effortlessly handle various fabrics. Furthermore, its automated function ensures seamless operations and guarantees that there is no distortion. By connecting the machine to a computer, users can easily create and produce customized designs with great ease and accuracy.

5. Intelligent typesetting technology with high efficiency and material saving; after designing the pattern, the software automatically arranges the pattern to fit closely, reducing waste; maximizing material saving, production efficiency and production cost are optimized.

6. The laser laser cutting machine laser head position can be adjusted at will, easy to operate. The latest operating software controls the power of the laser head, which makes the cutting effect of the two laser heads perfect, and the double-head work makes the work efficiency multiplied.

7. Configure the imported PMI guide rail, not only the motor and the drive make the leather laser cutting machine run more stable, ensuring balanced and efficient processing.

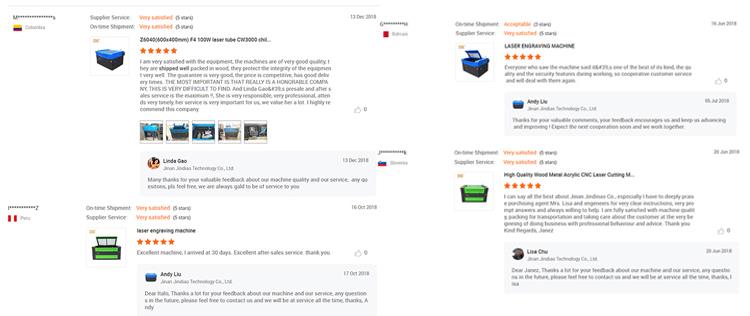

4. Service of JD laser engraving cutting machine:

1. warranty for 3 years.

2. Maintenance for whole life.

3. We will provide the consumable parts at an agency price.

4. 24 hours online service, free technical support.

5. Machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, pls kindly tell me.

6.We have manual instruction and CD (Guiding Videos) for software Installation, operation and machine's using and maintenance

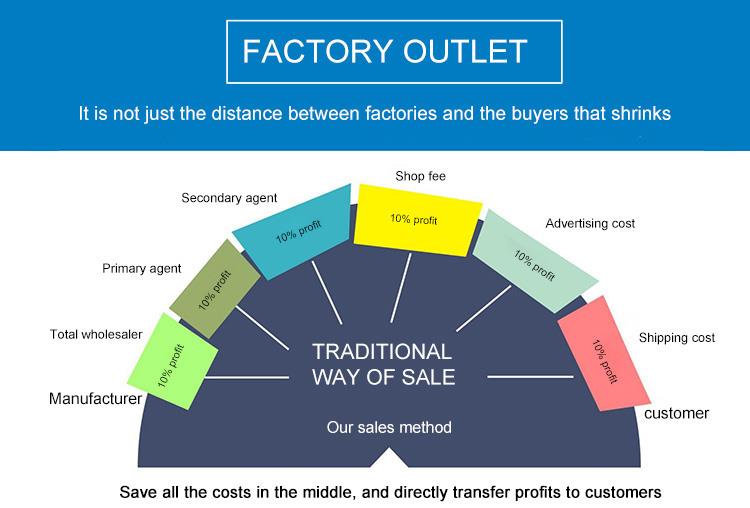

7. Company Information

· Founded in 2002.

· Has developed to a Large-scale International Manufacturing company.

· More Accuracy,More Automatically and Higher Quality Products with Intimate After-sales Service

· Jindiao Be The Leader Of Laser Industry

· Earn the Best Reputation and World-wide Trusted Customers.

· Jindiao laser machines cover all Chinese market and also very popular in America,West Europe,South Asian,East Asian etc. More Than 150 Countries

8.RFQ

1.Do I need different laser system for engraving or cutting?

No, you don’t need different laser system, because our laser machine is used for both engraving

and cutting, one machine for both kind of jobs

2. What is the laser software of your machine?

The laser software is Rdworks V8.

3. How can I choose the best machine for me?

There are three key questions to ask yourself when deciding on a machine:

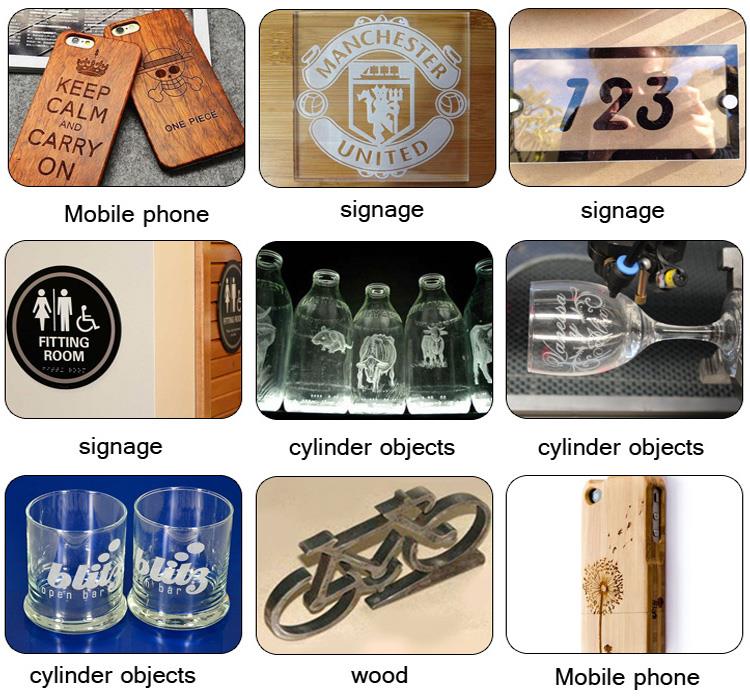

What is your primary use (cutting, engraving etc.)?

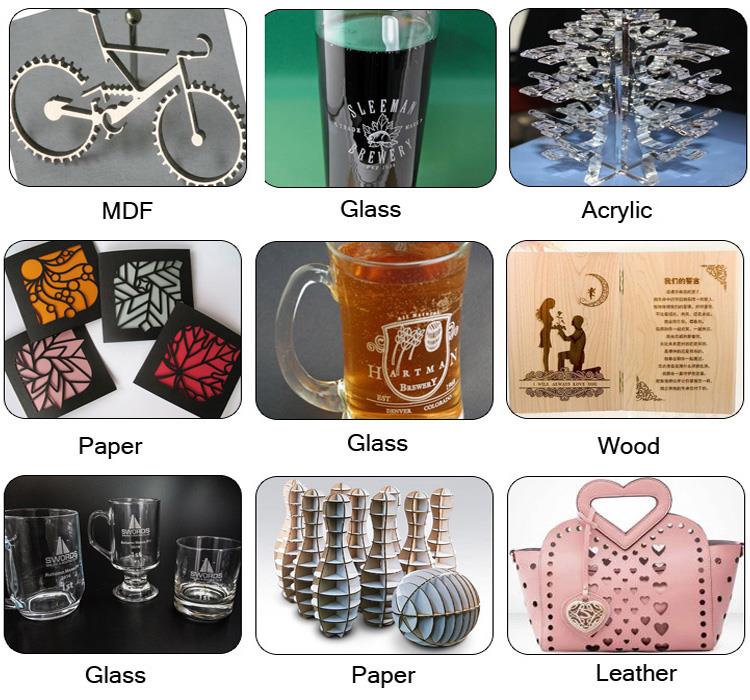

Which materials are you looking to work with?

What size of material do you need to process?

Please contact us and speak to our sales team for more advice.

4. How to pay you?

1. For ordering the machine, you can pay us by T/T.

2. For ordering the parts in the future, you can pay us by Paypal, Western Union or Moneygram.

5. Is there any warranty on your machine or parts?

1. The warranty of the machine is 24 months

2. The warrany of the laser tube is 6~10 months.

3. The warranty of the lens & mirrors is 3 months.

4. During warranty, we will send you new parts to you for replacing free of charge.

6.Are you a factory or trading company?

We are factory who has export authority and our own brand : “ZING”. Welcome visit our factory

and talk details about cooperation.

Color is optional and can be customized

Please contact us if you have other special requirements

Send Inquiry

You Might Also Like