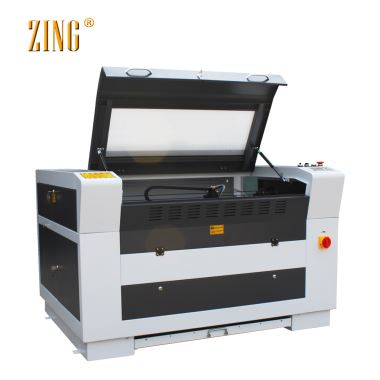

cnc router for metal cutting

Looking for a high-quality aluminum CNC router that can cut through tough metal? Look no further than China Zing's state-of-the-art cutting machines. Our computer-controlled routers are perfect for a range of materials, including wood, composites, aluminum, steel, plastics, and foams. With...

Description

Looking for a high-quality aluminum CNC router that can cut through tough metal? Look no further than China Zing's state-of-the-art cutting machines. Our computer-controlled routers are perfect for a range of materials, including wood, composites, aluminum, steel, plastics, and foams. With precision cutting capabilities and advanced technology, our CNC router is the perfect tool for any project. Whether you're a professional fabricator or a DIY enthusiast, you can trust China Zing to provide you with the best-in-class cutting performance.

The technical parameter for the Z1325B CNC router designed for steel is a crucial aspect to consider before purchasing this machine. It offers incredible features that are tailored to suit various steel cutting needs effectively. | |

Model | Z1325B |

X,Y working area | 1300x2500mm |

Z Max working area | 200 mm |

Table size | 1400x3000mm |

Working-holding | mechanical clamps |

Operating System | Mach 3 control system |

Working Voltage | AC220V/50Hz |

Working delicacy | 0.05mm |

X,Y,Z repositioning Positioning Accuracy | 0.05mm |

Frame | Groove steel structure |

X,Y,Z Structure | Three-axis square orbit, Gear-wheel driver |

Driver | Step Drivers |

Spindle Power Motor | 3.0 KW water cooling spindle. (optional: 2.2KW,4.5KW) |

Spindle Speed | 0-24000RPM |

Power (not include the spindle) | 1500W |

Command Language | G cord*.u00*.mmg*plt |

Running Environment | Temperature: 0 ~ 45 Relative humidity: 30% ~ 75% |

Surrounding for software | Windows98/2000/xp |

Cutters | 10(3D)。,。 |

A CNC router for metal cutting is a cutting machine specifically designed for cutting and shaping various types of metal materials. It utilizes computer numerical control (CNC) technology to control the movement of the cutting tool and precisely cut metal pieces according to the programmed instructions. |

Product Features of Z1325B: |

As part of the large scale material processing capabilities, the X and Y axis can be extended. This is facilitated by incorporating high-performance components sourced internationally, resulting in a cost-effective solution. |

● Equipped with durable domestically manufactured water-cooled spindles, these machines offer impressive power and rigidity. Their excellent adaptability makes them suitable for engraving and cutting on density boards, solid wood panels, and even creating intricate designs on 3D antique-style furniture. To generate highly similar content, we rearrange the provided information while maintaining the essence of the original text. |

The machine is driven by double motors and smoothly transmitted by double axis, ensuring that it does not become deformed or shaky even after prolonged use. |

The cutting process can sometimes become too hot, which is why the flume is preferred as a better option for cooling down the cutter while it's in use. Its unique design and effectiveness make it an ideal tool for ensuring that the temperature of the cutter is kept within a safe range, allowing for optimal performance without risking damage due to overheating. |

Field of application cnc router for aluminum: |

Various industries, such as advertising, seal making, crafts, gift making, and art moulds, benefit from the use of molds made of materials like stone, imitation stone, metal, and aluminum. These molds allow for the creation of intricate designs on materials like acrylic, double-color board, PVC, and ABS board. Additionally, wood working and molding industries can also utilize these molds to achieve precise and detailed designs. The range of applicable materials and industries highlights the versatility and importance of the use of molds in various fields.

Samples of cnc router steel: |

Send Inquiry

You Might Also Like