laser cutting machine for leather

The leather laser cutting machine is an innovative device that utilizes a crawler-type working platform with a two-head mutual-shift function. With the automatic discharging system, this cutting machine provides fast cutting speed, high fabric utilization rate, and automatic feeding system for...

Description

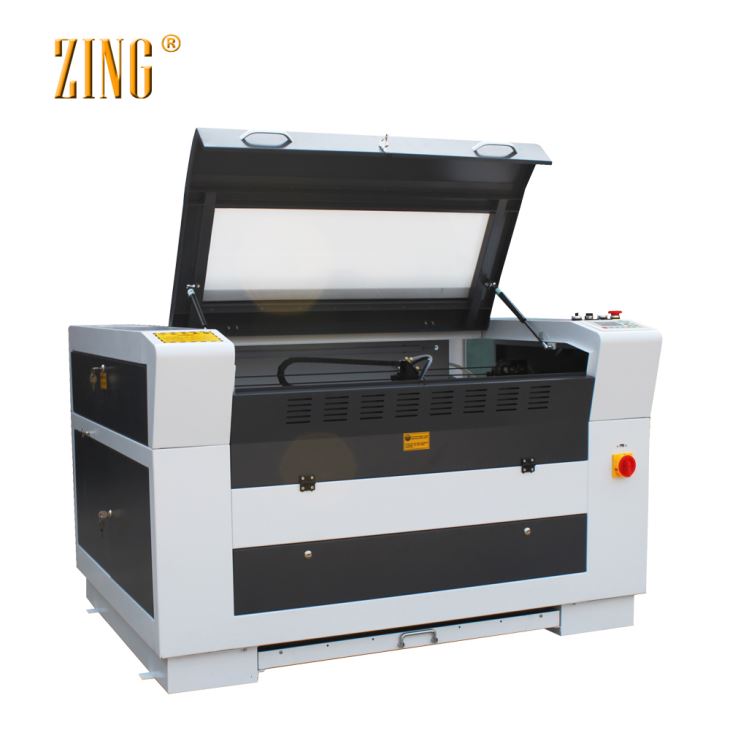

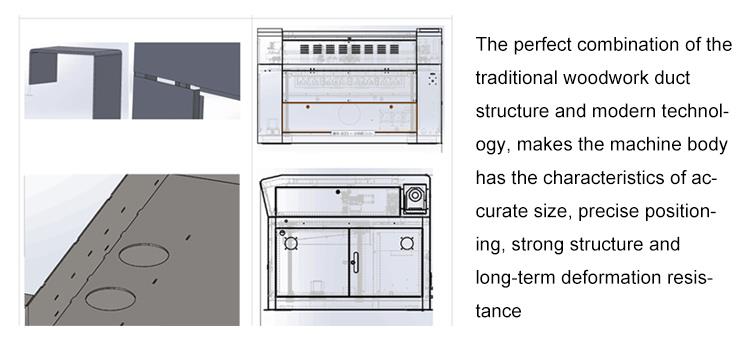

The leather laser cutting machine is an innovative device that utilizes a crawler-type working platform with a two-head mutual-shift function. With the automatic discharging system, this cutting machine provides fast cutting speed, high fabric utilization rate, and automatic feeding system for continuous feeding and cutting. It is specifically designed to cut materials such as plush materials and composite fabrics. The double laser head mutual shifting processing ensures efficient cutting while the automatic feeding system adds to its convenience. Overall, the leather laser cutting machine is a perfect addition to any operation that requires precision and efficiency in cutting leather and other materials.

The technical parameters of a garment laser cutting machine are vital in ensuring its optimal performance. These parameters are a set of specifications that describe the machine's features and capabilities. Understanding these parameters is crucial in selecting the appropriate machine for the desired application. | |

Product model | Z1850 |

Max working area(mm) | 1800x5000 |

Laser power | 60W/80W/100W/130W/150W/180W |

Laser Types | Hermetic And Detached CO2 Laser Tube |

Engraving speed(mm/min) | 0-75000 |

Cutting speed(mm/min) | 0-40,000 |

Minimum letter | English 1 x 1mm |

Location precision | ≤0.01mm |

Resetting positioning accuracy | 0.01mm |

Driving system | Stepper |

Software | Lasercut 5.3 or RDworks V8 |

360°slope engrave | Yes |

Power supply | AC 220V(or 110V)/50~60HZ |

Operating temperature | 0 - 45℃ |

Operating humidity | 5 - 95% |

Laser output control | 1-100% control panel and software setting |

Highest scanning precision | 50-1000DPI |

Compatible software | CorelDraw, AutoCAD, Photoshop |

Auxiliary Devices | Exhaust fan and Exhaust pipe |

Cooling mode | Water-cooling and protection system |

Operating system | Window 98/ME/2000/XP/VISTA/2007 |

Graphic format supported | There are a variety of file formats that are commonly used in design and embroidery software. Some of these formats include BMP, CIF, JPEG, TGA, TIFF, PLT, AI, DXF, DST (TIANDAO Embroidery Software), DWG, CDR, and more. Each of these formats has its own advantages and uses, depending on the type of design or project you are working on. Some may be better suited for vector graphics, while others may be more appropriate for photographs or other types of images. It's important to understand the strengths and limitations of each file format in order to choose the best one for your project. |

Accessories | Water pump, air pump, exhaust fan, base, wheel etc |

Product Features of laser textile cutting machine: |

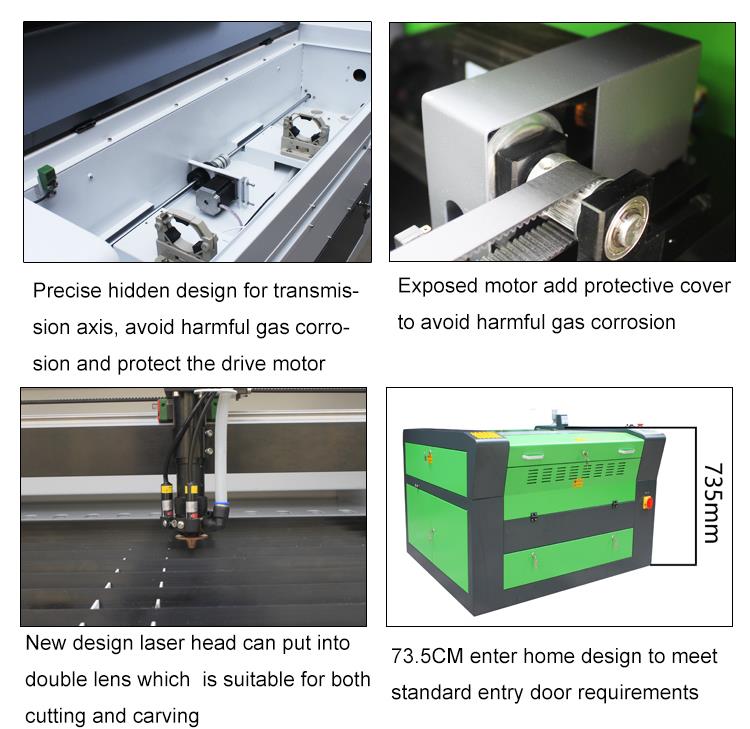

The leather laser cutting machine operates by emitting a highly concentrated beam of light that is focused into a small spot. The result of this is a power density at the focus that is very high. The majority of the heat generated by the beam is absorbed by the material being cut and very little is reflected, conducted or diffused. This causes the material to quickly reach a temperature high enough to vaporize and form a hole. As the beam moves over the material in a linear manner, these holes come together to form narrow slits. The cutting process is such that there is minimal heat transfer to the material resulting in minimal deformation.

During the cutting process, an auxiliary vapor body is incorporated to aid in cutting the material effectively. The vapor used is dependent on the type of material being cut. For cutting steel, oxygen is used as the auxiliary vapor to produce an exothermic chemical reaction that oxidizes the material, resulting in the removal of slag within the slit. In contrast, cutting polypropylene requires compressed air while cutting flammable substances like cotton and paper requires an inert gas.

The introduction of the auxiliary vapor into the nozzle serves a crucial role, cooling down the focusing lens, which simultaneously prevents smoke from entering the lens holder and contaminating the lens. If the lens contaminated and overheat, it could lead to further complications during the cutting process. Therefore, the use of an auxiliary vapor in laser cutting ensures the smooth and effective cutting of materials while ensuring the safety of the process.

Most organic and inorganic materials can be laser cut. In the metal processing industry where industrial manufacturing systems are heavily weighted, many metal materials, regardless of their hardness, can be cut without distortion. Of course, for high reflectivity materials such as gold, silver, copper and aluminum alloys, they are also good heat transfer conductors, so laser cutting is difficult or even impossible.

Send Inquiry

You Might Also Like