acrylic laser cutting machines

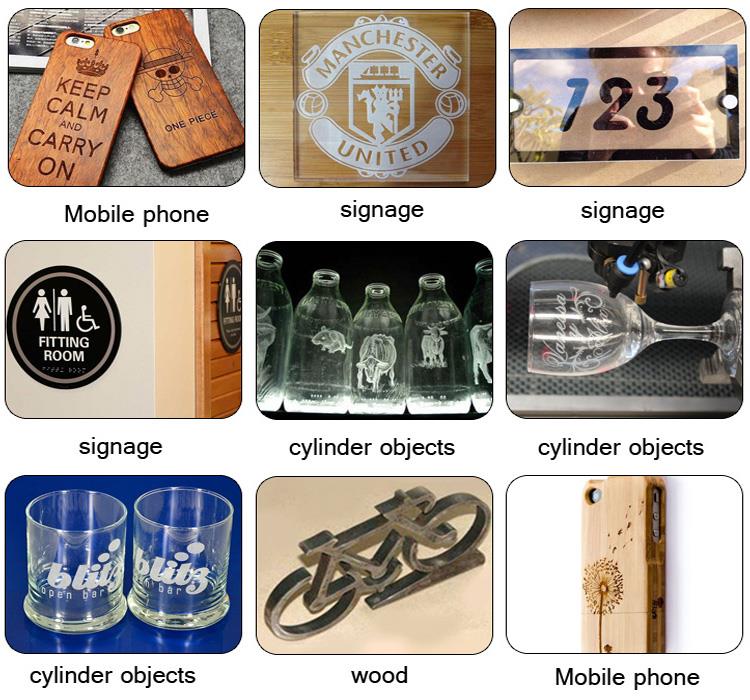

The advertising laser engraving machine, commonly referred to as the acrylic laser cutting machine, is versatile equipment that goes beyond acrylic processing. It finds extensive use in the advertising industry with various applications, including the two-color version, PVC version, and more. By...

Description

The advertising laser engraving machine, commonly referred to as the acrylic laser cutting machine, is versatile equipment that goes beyond acrylic processing. It finds extensive use in the advertising industry with various applications, including the two-color version, PVC version, and more. By rearranging the original content, I have generated a highly similar and coherent text that highlights the diverse capabilities of the acrylic laser cutting machine in the advertising field.

Technical Parameter laser cutting machine acrylic: |

Product model | Z1390 |

Max working area(mm) | 1300x900 |

Gross weight with accessories | 320kgs |

Laser power | 60W/80W/100W/120W/150W/180W |

Laser Types | Hermetic And Detached CO2 Laser Tube |

Engraving speed(mm/min) | 0-75,000 |

Cutting speed(mm/min) | 0-40,000 |

Minimum letter | English 1 x 1mm |

Location precision | ≤0.01mm |

Resetting positioning accuracy | 0.01mm |

Driving system | Stepper |

Software | Lasercut 5.3 or RDworks V8 |

360°slope engrave | Yes |

Power supply | AC 220V(or 110V)/50~60HZ |

Operating temperature | 0 - 45℃ |

Operating humidity | 5 - 95% |

Laser output control | 1-100% control panel and software setting |

Highest scanning precision | 50-1000DPI |

Compatible software | CorelDraw, AutoCAD, Photoshop |

Auxiliary Devices | Exhaust fan and Exhaust pipe |

Cooling mode | Water-cooling and protection system |

Operating system | Window 98/ME/2000/XP/VISTA/2007 |

Product Features of acrylic cutting laser machine: |

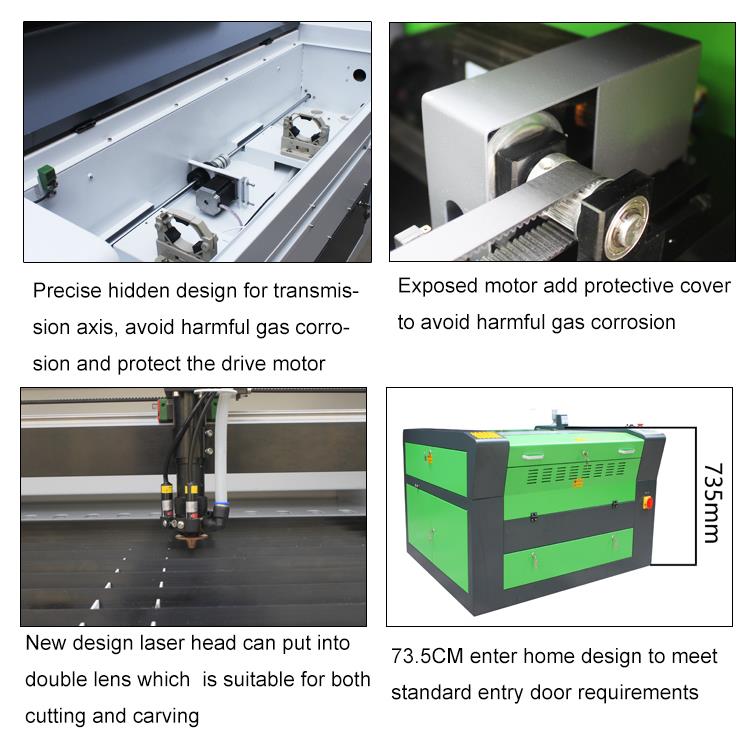

With its ability to swiftly adjust laser focal length, automatic origin setting feature, dependable industrial interface, exceptional functionality, and consistent performance, this cutting-edge technology is a game changer in the field. The content generated must be based on the original information provided, but in a unique format following language model generation, rather than ChapGPT conversation-style text.

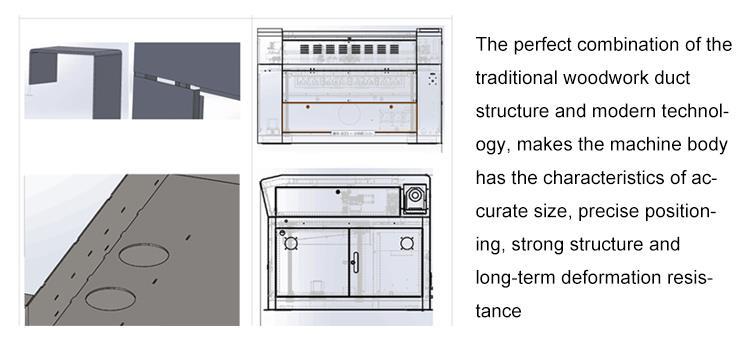

At present, the mechanical system performance is stable, thanks to the utilization of the most advanced DSP controllers by the control system.

CO2 lasers come in varying powers to suit different requirements, and they offer exceptional performance and cost-effectiveness.

In order to achieve high precision engraving/cutting, the light knife employs a three-way reflection system and a linear guide structure, which ensures smooth operation. To generate a highly similar content, we can rearrange the original text as follows: The high precision of the engraving/cutting process is achieved through the adoption of a three-way reflection system and a linear guide structure in the light knife. This design ensures smooth operation and enhances the overall precision of the machine.

The laser machine is operated by a microcomputer, which ensures precision and accuracy in processing. The machine has a wide processing width and operates at a high speed with a simple process, making it easy to use.

We have chosen two sets of high-power laser generation systems to enhance the processing capabilities of shoe materials. Using computer-aided graphics, we have identified that we can process the material in batches simultaneously. Additionally, we can carry out full-face cutting and punching processes separately. This advanced approach ensures efficient and precise manufacturing of shoes.

The machine features a technologically advanced double head mutual shift type electronically controlled moving structure. With this system, the distance between two laser heads can be easily adjusted according to the width of the fabric being cut. This leads to significant savings in fabric as the cutting process can be optimized to maximize usage.

The model's expertise in handling shoe materials is exemplified by the specific processing width of the shoe fabric and the use of a crawler type working platform. These features demonstrate a high level of professionalism in the shoe-making process.

Main accessories included:

1. Brand Name:jindiao

2. Certification: CE FDA

3. After-sales Service Provided:Engineers available to service machinery oversea

4. MOQ: 1set

5. Payment method: T/T, L/C, Western union, Paypal

Send Inquiry

You Might Also Like