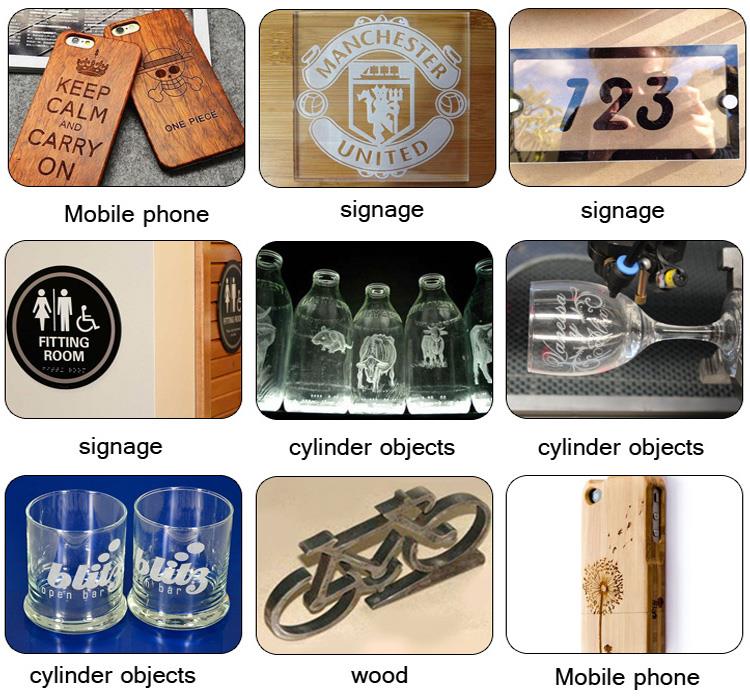

laser cutting machine for acrylic

Acrylic laser cutting machines are designed specifically for cutting non-metal materials. These machines are equipped with imported step motors and belt drives, ensuring precise and efficient operation. The guide rail structure is carefully designed to ensure optimal performance. Additionally,...

Description

Acrylic laser cutting machines are designed specifically for cutting non-metal materials. These machines are equipped with imported step motors and belt drives, ensuring precise and efficient operation. The guide rail structure is carefully designed to ensure optimal performance. Additionally, the machines are equipped with a new traditional mixing system that enhances cutting speed without compromising the quality of the cut, even for small circles and straight lines. With excellent rigidity, high speed, and a wide processing range, these machines provide stability and reliable performance for all your acrylic cutting needs.

Technical Parameter: | |

Product model | Z1612 |

Max working area(mm) | 1600x1200 |

Laser power | 60W/80W/100W/120W/150W/180W |

Laser Types | Hermetic And Detached CO2 Laser Tube |

Engraving speed(mm/min) | 0-75,000 |

Cutting speed(mm/min) | 0-40,000 |

Minimum letter | English 1 x 1mm |

Location precision | ≤0.01mm |

Resetting positioning accuracy | 0.01mm |

Driving system | Stepper |

Software | Lasercut 5.3 or RDworks V8 |

360°slope engrave | Yes |

Power supply | AC 220V(or 110V)/50~60HZ |

Operating temperature | 0 - 45℃ |

Operating humidity | 5 - 95% |

Laser output control | 1-100% control panel and software setting |

Highest scanning precision | 50-1000DPI |

Compatible software | CorelDraw, AutoCAD, Photoshop |

Auxiliary Devices | Exhaust fan and Exhaust pipe |

Cooling mode | Water-cooling and protection system |

Operating system | Window 98/ME/2000/XP/VISTA/2007 |

Features: |

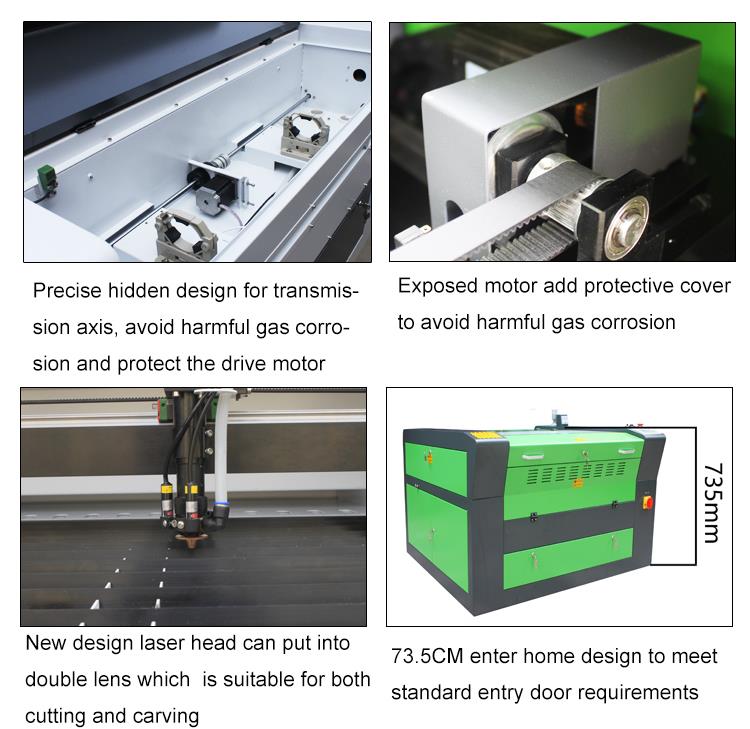

The use of an advanced international controller has significantly enhanced performance. The software design incorporates a smooth S-type acceleration/deceleration control for faster and more stable action. Additionally, the automatic light decay compensation technology ensures that desired cutting effects are achieved across various parts.

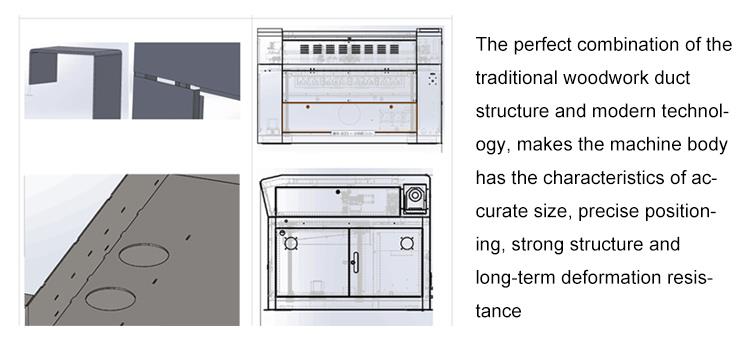

By utilizing a combination of internal and external rail drive system, the rail system structure becomes more lightweight, resulting in improved machine processing speed and enhanced stability.

With the use of imported stepper motor and belt drive, along with the rail structure imported specifically for this purpose, the laser processing speed and accuracy performance have witnessed significant improvements.

The electrical components in use are imported brands, which greatly enhances the anti-electric interference ability due to the standardized industrial wiring employed. This is a stark contrast to the tangled mess of wires and cable boxes often seen in products from small manufacturers.

By implementing imported lenses, the heat loss during cutting is significantly reduced, resulting in a more efficient cutting process. Additionally, the lenses are lighter in weight, further enhancing the cutting effect.

Our product comes with a built-in jog function and allows for continuous engraving even in the case of power outages. The work preview function allows you to preview your design before you start the engraving process, and the dynamic display of processing trajectory and coordinate points helps you keep track of your progress in real-time. With our product, you can also easily monitor and track your processing progress with a convenient display feature that shows you the progress of your engraving at any given time.

Maintenance:

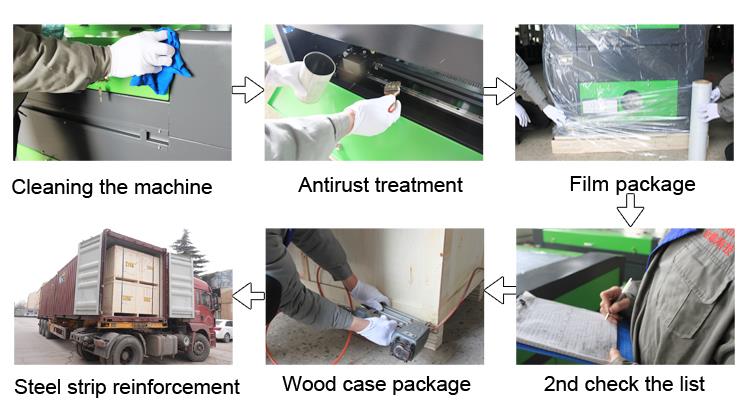

To ensure that the machine functions properly over the long term, it's important to pay attention to how it's maintained and used. Regular cleaning and maintenance are crucial to keeping the machine in good condition. Neglecting these tasks can lead to malfunctions and breakdowns. Therefore, it's highly recommended that you take the time to properly care for your machine to avoid any unnecessary issues down the line. By taking a proactive approach to maintenance and cleaning, you can help ensure that your machine performs optimally and continues to operate smoothly for years to come.

(1) The lens should be cleaned in time

(2) Fan cleaning in time

(3) Pay attention to the replacement of water and the cleaning of the water tank

(4) Cleaning of the guide rail

(5) Fastening of screw coupling

(6) Inspection of the light path

Send Inquiry

You Might Also Like