stainless steel laser cutting machine

Description: The primary category of the stainless steel laser cutting machine is metal cutting machines, specifically designed for cutting stainless steel. This machine efficiently utilizes the laser beam's absorption by stainless steel to achieve precise cutting outcomes. The high-speed and...

Description

Product model | JD1320 | JD1325 | JD1630 |

Max working area(mm) | 1300x2000 | 1300x2500 | 1600x3000 |

Laser power | 60W/80W/100W/130W/150W/180W | ||

Laser Types | Hermetic And Detached CO2 Laser Tube | ||

Engraving speed(mm/min) | 0-75000 | ||

Cutting speed(mm/min) | 0-40,000 | ||

Minimum letter | English 1 x 1mm | ||

Location precision | ≤0.01mm | ||

Resetting positioning accuracy | 0.01mm | ||

Driving system | Stepper | ||

Software | RD works V8 | ||

360°slope engrave | Yes | ||

Power supply | AC 220V(or 110V)/50~60HZ | ||

Operating temperature | 0 - 45℃ | ||

Operating humidity | 5 - 95% | ||

Laser output control | 1-100% control panel and software setting | ||

Highest scanning precision | 50-1000DPI | ||

Compatible software | CorelDraw, AutoCAD, Photoshop | ||

Auxiliary Devices | Exhaust fan and Exhaust pipe | ||

Cooling mode | Water-cooling and protection system | ||

Operating system | Window 98/ME/2000/XP/VISTA/2007 | ||

Graphic format supported | You can use various file formats with our TIANDAO Embroidery Software, including BMP, CIF, JPEG, TGA, TIFF, PLT, AI, DXF, and DST. Additionally, we support file types like DWG and CDR for your convenience. No matter what kind of design or artwork you have, our software can help you create beautiful and intricate embroidery. So why not give it a try today? | ||

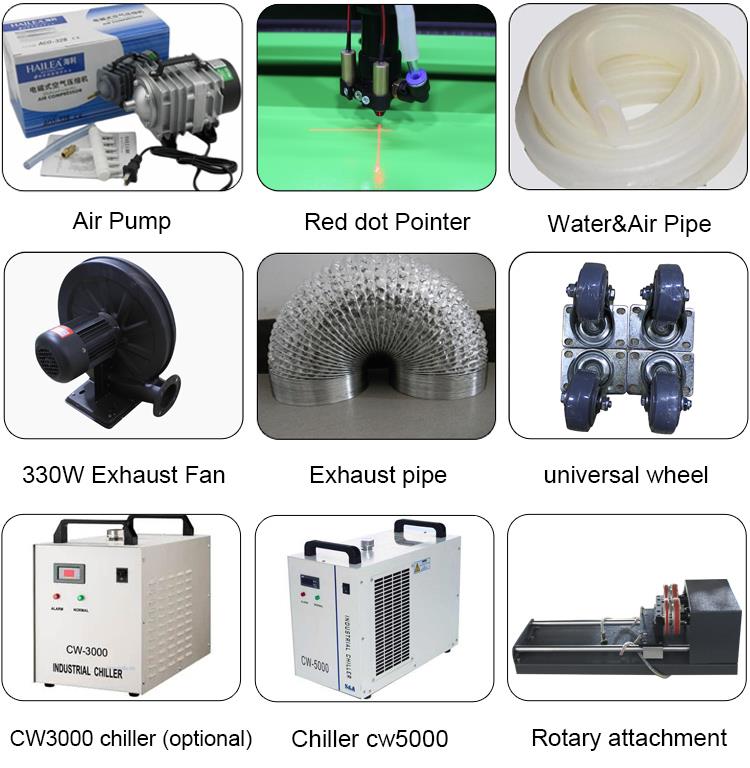

Accessories | Water pump, air pump, exhaust fan etc | ||

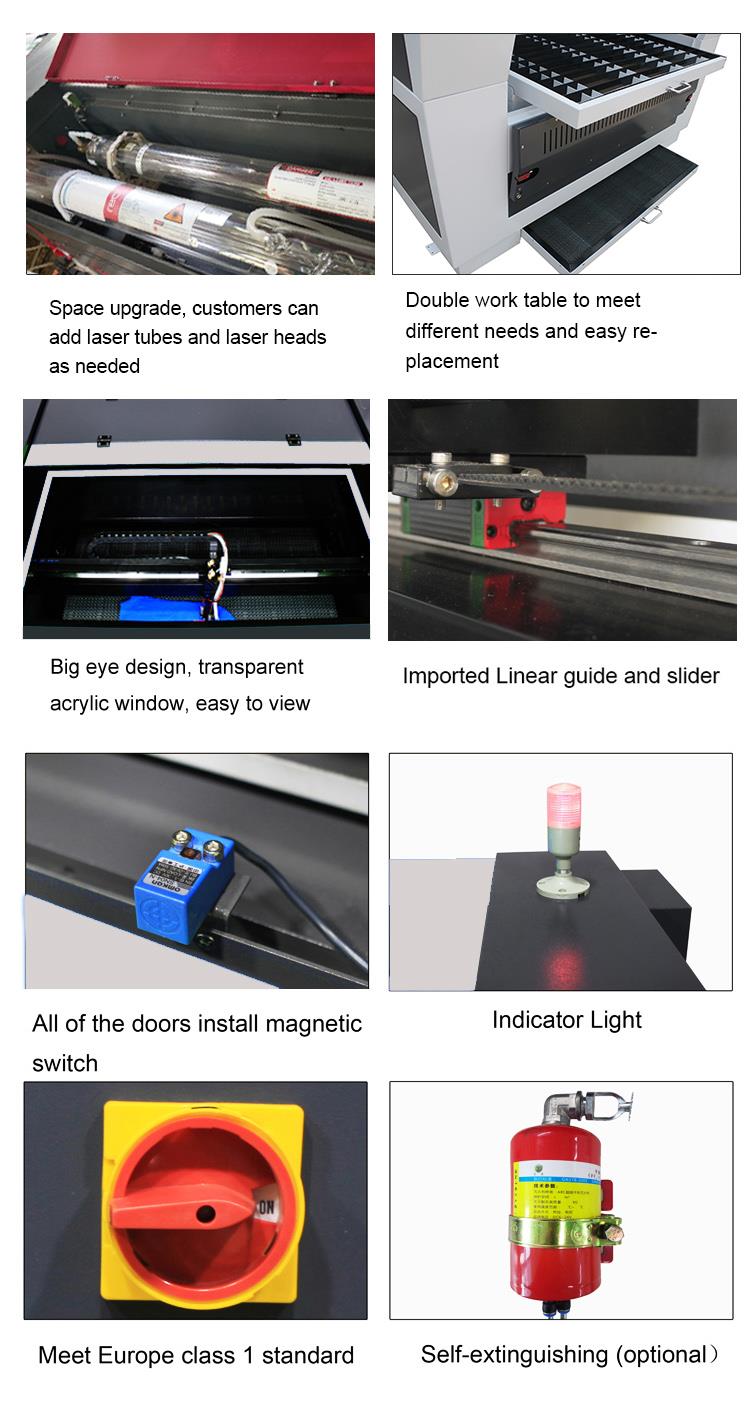

Description:

The primary category of the stainless steel laser cutting machine is metal cutting machines, specifically designed for cutting stainless steel. This machine efficiently utilizes the laser beam's absorption by stainless steel to achieve precise cutting outcomes.

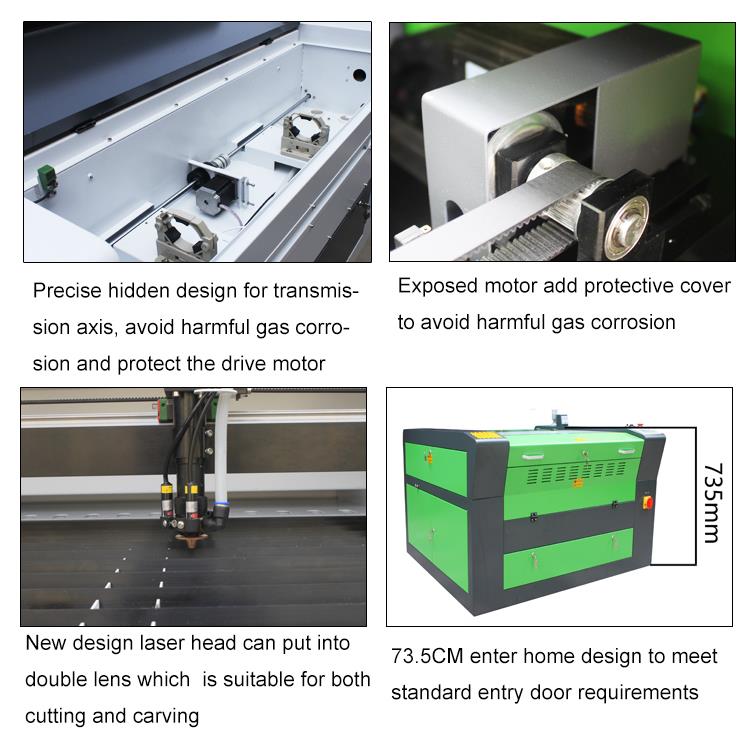

The high-speed and stable laser cutting process is ensured by the industrial machine tool design. With the capability to accommodate fiber lasers of various powers, this machine can efficiently cut and punch a wide range of metals and materials with high precision. Additionally, the cutting process is enhanced by the inclusion of a dynamic focusing device, which enables a consistent maintenance of cutting quality. Overall, this large-format laser cutting machine is a cost-effective solution for industries requiring precise and efficient cutting operations.

During the cutting process, the iron present in stainless steel undergoes an exothermic reaction with oxygen. However, the chromium oxidation in stainless steel has a unique property of preventing oxygen from penetrating the inner layers of the material. As a result, the amount of oxygen entering the molten layer is reduced, leading to incomplete oxidation of the molten layer and thus reducing the reaction rate. This reduction in reaction leads to an increase in cutting speed compared to low carbon steel.

However, achieving a completely non-stick slag when cutting stainless steel is challenging. Although satisfactory cutting results can be obtained by using higher laser power and oxygen pressure, a completely non-stick slag is difficult to achieve. An alternative approach is to use inert gas as an auxiliary gas during stainless steel cutting. This allows for non-oxidized trimming, which can be directly used for welding purposes. However, it should be noted that using an inert gas as an auxiliary gas leads to a reduction in cutting speed by approximately 10% compared to when oxygen is used.

To summarize, cutting stainless steel involves an exothermic reaction between iron and oxygen. The presence of chromium prevents excessive oxygen penetration, reducing the reaction rate and increasing cutting speed. While satisfactory cutting results are achievable, obtaining a completely non-stick slag is challenging. Using an inert gas as an auxiliary gas allows for non-oxidized trimming but reduces cutting speed compared to oxygen usage.

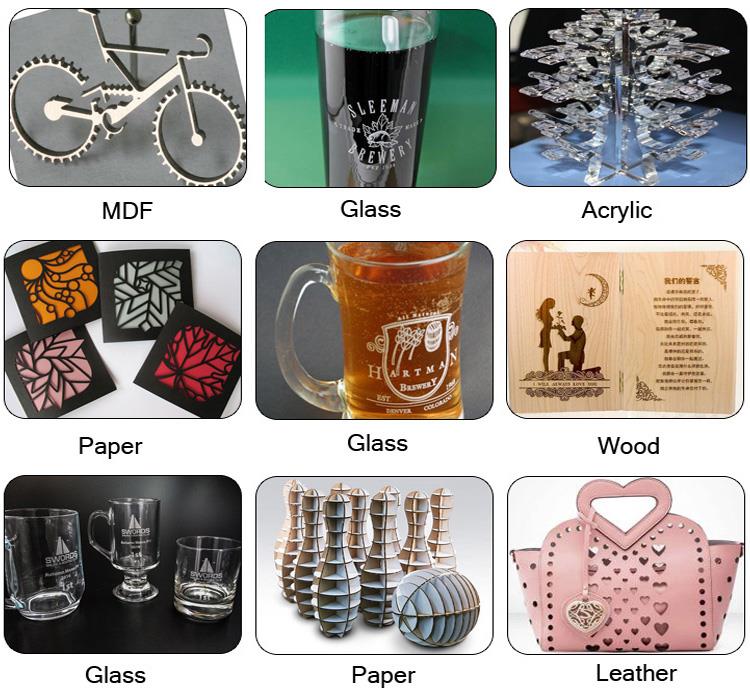

Application range

Suitable for high precision cutting of various metal materials.

Send Inquiry

You Might Also Like