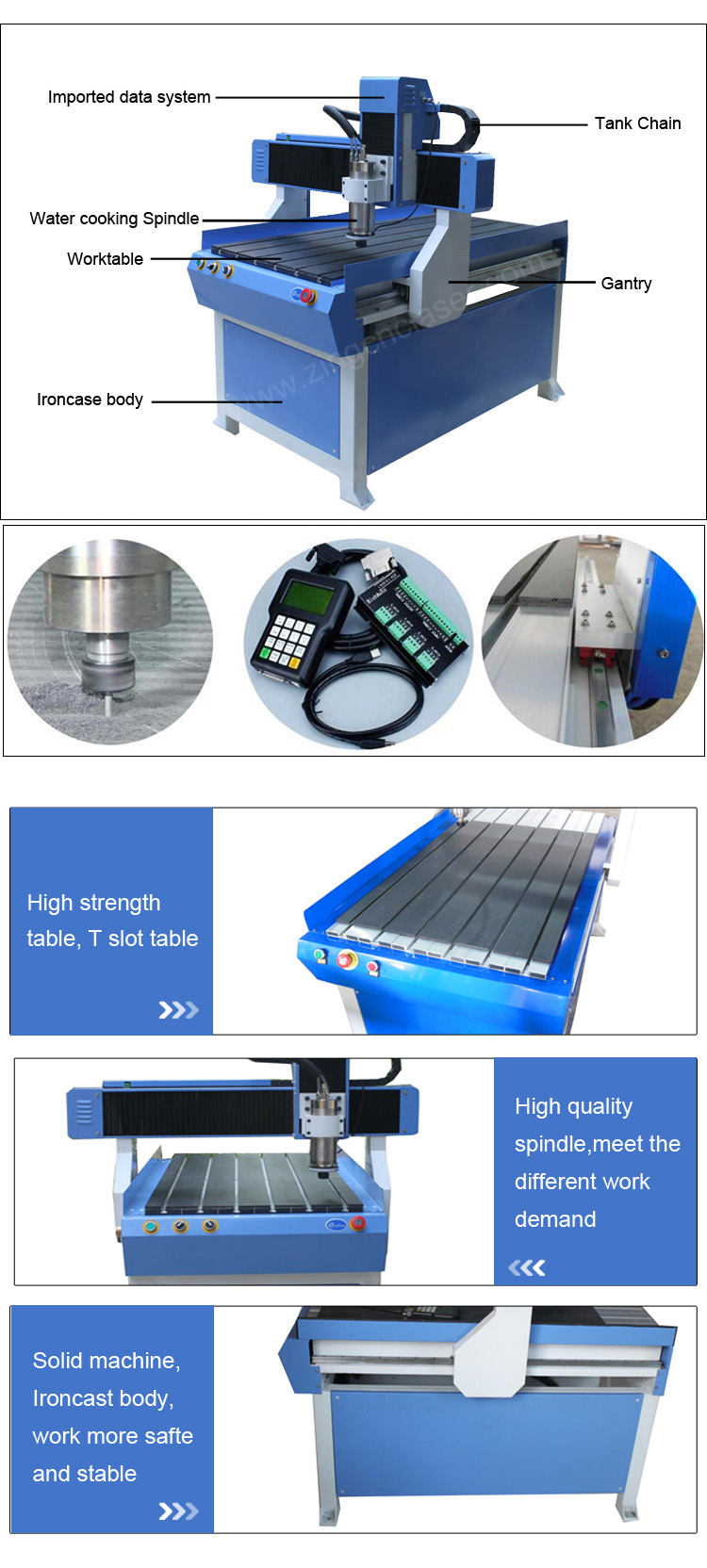

3d cnc wood carving machine

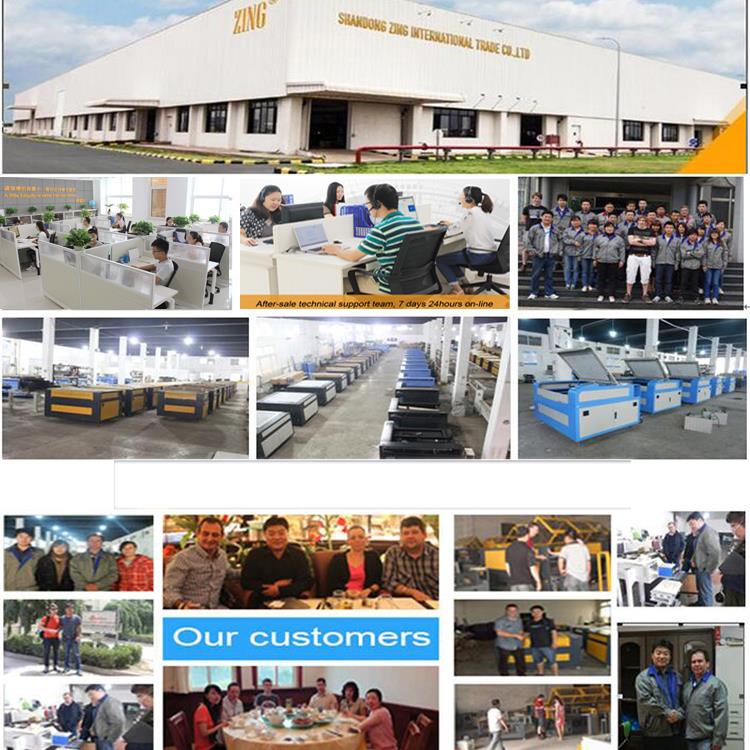

Are you in search of a 3D CNC wood carving machine or a small CNC router for wood? Look no further, as Zing offers top-notch quality and cost-effective options. With over 15 years of experience in manufacturing CNC routers, Zing has established itself as a trusted factory. Rest assured, all of...

Description

Are you in search of a 3D CNC wood carving machine or a small CNC router for wood? Look no further, as Zing offers top-notch quality and cost-effective options. With over 15 years of experience in manufacturing CNC routers, Zing has established itself as a trusted factory. Rest assured, all of our CNC routers come with CE and FDA certifications, ensuring their safety and reliability. Trust Zing for the best quality and affordable CNC machines for your woodworking needs.

Product Features of small wood cnc machine: |

The German double nut and ball bearing guide screw are a perfect match. The excellent compatibility of these two components ensures smooth and precise movement. You can rely on the German double nut and ball bearing guide screw for reliable and efficient performance. These components work together seamlessly to provide optimal functionality in various applications. Their compatibility is unmatched, making them the ideal choice for your needs. Embrace the superiority of the German double nut and ball bearing guide screw for exceptional results. |

One of the key features of this product is its adoption of a straight line guide rail. This rail has a load-bearing surface that makes surface contact, which in turn gives it a life expectancy that is 2200 times longer than conventional rails. Even with continuous use over an extended period of time, the rail retains its precision, ensuring optimum performance throughout. |

High speed drive motors are employed, increasing their velocity by nearly 2 meters compared to the original model. |

The X axis has been equipped with the renowned dustproof structure to ensure long-term performance. This guarantees that the axis functions effectively over an extended period of time. |

To ensure that the blade breakage or delay situation is processed, memory is necessary. A storage system must be in place to handle such occurrences effectively. |

This machine offers fantastic compatibility, making it highly versatile. It can work seamlessly with various programs, including CAD, CAM, Type3, Corelerow, and more, enabling users to produce fine relief, 2D, and 3D products effortlessly. Whether you're looking to create intricate designs or simple projects, this machine has got you covered. Additionally, its compatibility with numerous software options ensures that users can choose the program that best suits their needs. With this machine, you'll have the flexibility and freedom to bring your creative ideas to life. |

Technical Parameter of small cnc rotuers for wood: | |

Model | Z6090L |

X,Y working area | 600x900mm |

Z Max working area | 100mm |

Table size | 800x1100mm |

Working-holding | mechanical clamps |

Working delicacy | 0.05mm |

X,Y,Z repositioning Positioning Accuracy | 0.05mm |

Frame | Groove steel structure |

X,Y,Z Structure | Y-axis square orbit, Ball-Screw driver |

Driver | Step Driver |

Spindle Power Motor | 1.5 KW water cooling spindle. (optional: 2.2KW, 3KW) |

Working Voltage | AC220V/50Hz |

Power (not include the spindle) | 1200W |

Spindle Speed | 0-24000RPM |

Drive Motors | Stepper system ( optional: servo system) |

Command Language | G cord*.u00*.mmg*plt |

Operating System | March 3 control system |

Running Environment | The acceptable temperature range for operation is from zero to forty-five degrees Celsius, while the relative humidity should remain within the range of thirty to seventy-five percent. It is important to keep these environmental factors within the specified limits to ensure optimal performance. |

Surrounding for software | Windows98/2000/xp |

Cutters | We have a set of 10 pieces that include both a 3D cutter and a milling bottom cutter. To create a similar content, the original information can be rephrased as follows: Our product set comprises of 10 pieces which are accompanied by a 3D cutter and milling bottom cutter. |

A CNC machine is a revolutionary tool used for the precision cutting of wood. With its advanced technology and computer-controlled operation, it has transformed the woodworking industry. The CNC machine enables woodworkers to create intricate designs and shapes with incredible accuracy. |

Samples of cnc machine cuttign wood: |

![]()

Is it necessary for me to document the various cut and carving settings for different materials? I would like a similarly worded response, but with a different sentence structure and word choice based on the original text's information.

It was clear that we needed to incorporate a parameter library into the software to make things more efficient. Once we determined the suitable settings for a specific material, we could record it in the parameter library, allowing us to retrieve it quickly for future cuts of the same material. This capability reduced the need for time-consuming adjustments, as we could instantly access the proper settings. By utilizing the parameter library, we were able to improve productivity and streamline our operations.

2.Does your machine run on a laptop or a desktop?

Yes, as long as your computer operating system is Windows 2000 or XP or vista or win 7/8/10

3.Can your machine run on XP?

Our machine runs on Windows 2000 / XP/vista/win 7/8/10 32bits and 64bites system.But it does not support the Mac operating system (apple developed it).

4.What kind of software is used to design the project?

You can use both CorelDraw and AutoCAD to design all your artwork and then send it to RDWorks software to set the paramet

5.What format does the software support?

JPG, PNG, BMP, PLT, DST, DXF, CDR, AI, DSB, GIF, MNG, TIF, TGA,PCX, JP2, JPC, PGX, RAS, PNM, SKA, RAW

6.Will it engrave from a jpeg image?

Yes

7.Can I take a picture and engrave the image on an object without any hassles?

Yes, you can take a photo by using a camera and then load the photo to the software directly and engrave it.

8.Does machine comes ready to work?

the laser machine is ready to work, the exhaust fan and the air pump and the water pump are included. (But when you using a big power laser tube, it is suggested to buy a water chiller for cooling the laser tube)

9.How much time do I need to spend on learning how to run the laser machine?

As long as you know how to design jobs in graphic software, it just takes a few hours for you to become a master of laser machine. You just need to do some tests to know what speed and power is good for different materials. Since we’ve provided some of the parameter library, it will save you more time.You can watch the guiding videos from our website to learn how to use the machine in advance too.

10.Do I need separate laser systems for engraving and cutting?

No, our laser machine can do both cutting and engraving very well.You just need one machine for both kinds of jobs.

Send Inquiry

You Might Also Like