Laser Cutting Etching Machine for Wood

The Laser Cutting Etching Machine for Wood is a non-contact processing method. Compared with traditional machining methods, it has the advantages of no wood chip contamination, no tool wear, no need to change tools, and no noise pollution. The cutting engraving uses a cutting method to process...

Description

Technical Parameter laser etching wood machine: | |

Product model | Z1390 |

Max working area(mm) | 1300x900 |

Laser power | 60W/80W/100W/120W/150W/180W |

Laser Types | Hermetic And Detached CO2 Laser Tube |

Engraving speed(mm/min) | 0-75,000 |

Cutting speed(mm/min) | 0-40,000 |

Minimum letter | English 1 x 1mm |

Location precision | ≤0.01mm |

Resetting positioning accuracy | 0.01mm |

Driving system | Stepper |

Software | Lasercut 5.3 or RDworks V8 |

360°slope engrave | Yes |

Power supply | AC 220V(or 110V)/50~60HZ |

Operating temperature | 0 - 45℃ |

Operating humidity | 5 - 95% |

Laser output control | 1-100% control panel and software setting |

Highest scanning precision | 50-1000DPI |

Compatible software | CorelDraw, AutoCAD, Photoshop |

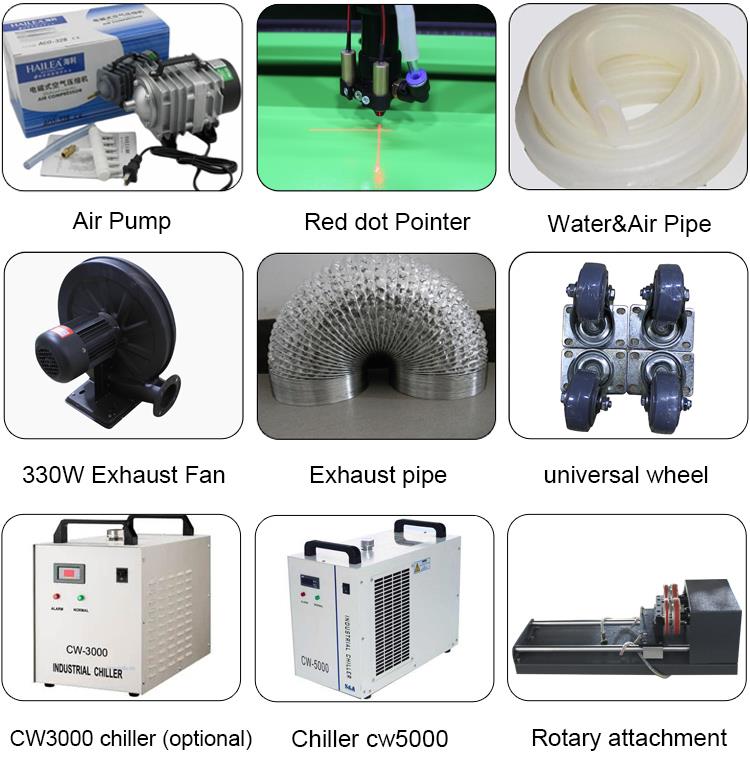

Auxiliary Devices | Exhaust fan and Exhaust pipe |

Cooling mode | Water-cooling and protection system |

Operating system | Window 98/ME/2000/XP/VISTA/2007 |

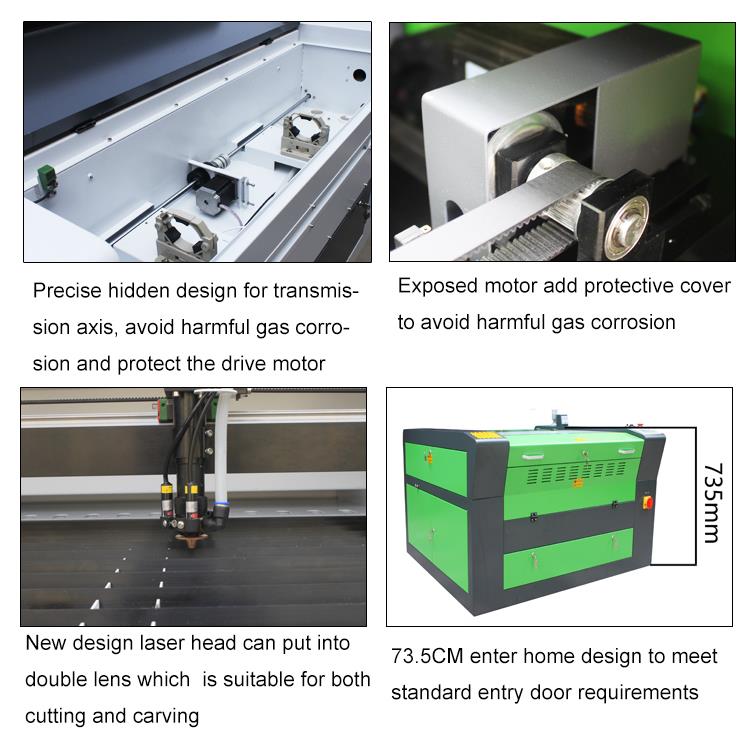

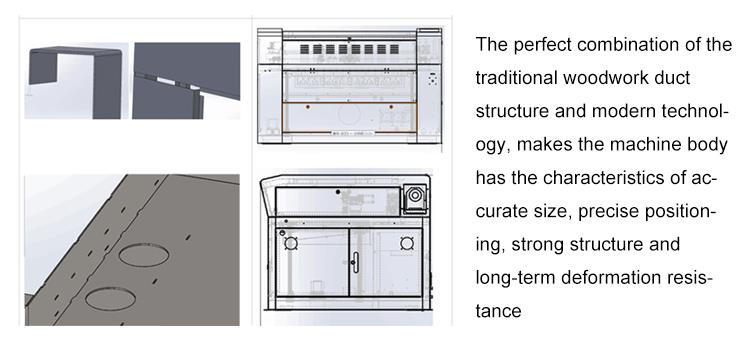

Product Features: |

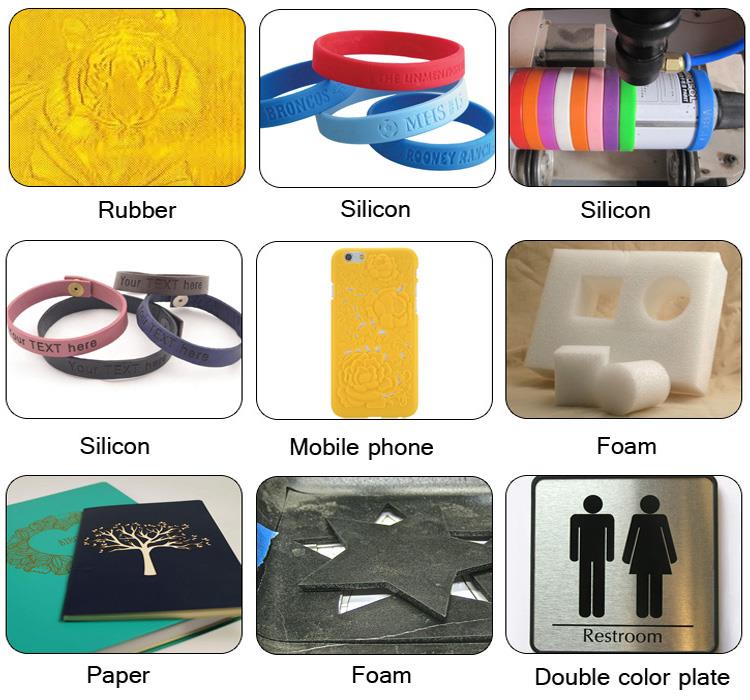

The Laser Cutting Etching Machine for Wood is a non-contact processing method. Compared with traditional machining methods, it has the advantages of no wood chip contamination, no tool wear, no need to change tools, and no noise pollution.

The cutting engraving uses a cutting method to process the desired pattern on the surface of the wooden material, that is, the pattern is first decomposed into a plurality of line forms, and then the lines are cut by a laser to obtain a pattern represented by the cutting line.

The Laser Cutting Etching Machine for Wood uses dot punching to engrave and has a natural edge in grayscale performance. As a result, in the engraving design, the gray scale expression is used as much as possible. The benefit is that on the one hand, the coloring process is shortened, saving time and money; on the other hand, the engraving expression means are expanded, and the graphics level is raised.

Each form of the wood sign has its unique qualities, some of which are dense, such as hardwood, requiring more laser power to engrave or cut. Before carving less known wood, we recommend understanding the engraving properties first.

Send Inquiry

You Might Also Like