ccd laser cutting machine

The arc processing technology has been optimized to enhance the quality of the cutting process. This automated system automatically adjusts the line segments, including curves and arcs, to ensure that the end result is smooth and exquisite. The cutting edges are improved to produce a flawless...

Description

Technical Parameter of co2 laser cutting machine: | ||

Product model | Z1390 | Z1612 |

Max working area(mm) | 1300x900 | 1600x1200 |

Gross weight with accessories | 320kgs | 360kgs |

Laser power | 60W/80W/100W/120W/150W/180W | |

Laser Types | Hermetic And Detached CO2 Laser Tube | |

Engraving speed(mm/min) | 0-75000 | |

Cutting speed(mm/min) | 0-40,000 | |

Minimum letter | English 1 x 1mm | |

Location precision | ≤0.01mm | |

Resetting positioning accuracy | 0.01mm | |

Driving system | Stepper | |

Software | Lasercut 5.3 or RDworks V8 | |

360°slope engrave | Yes | |

Power supply | AC 220V(or 110V)/50~60HZ | |

Operating temperature | 0 - 45℃ | |

Operating humidity | 5 - 95% | |

Laser output control | 1-100% control panel and software setting | |

Highest scanning precision | 50-1000DPI | |

Compatible software | CorelDraw, AutoCAD, Photoshop | |

Auxiliary Devices | Exhaust fan and Exhaust pipe | |

Cooling mode | Water-cooling and protection system | |

Operating system | Window 98/ME/2000/XP/VISTA/2007 | |

The arc processing technology has been optimized to enhance the quality of the cutting process. This automated system automatically adjusts the line segments, including curves and arcs, to ensure that the end result is smooth and exquisite. The cutting edges are improved to produce a flawless finish, making the process more efficient.

The mechanical structure of the ccd laser cutting machine is highly precise and reliable. The guide rail, made of mold aluminum, is resistant to deformation and ensures optimal stability during operation. High-quality components such as guide rails, rollers, and bearings from Japan and Singapore have been strategically integrated into the system to enhance the accuracy and precision of the transmission. These components work synergistically to ensure that the laser cutter delivers consistent, high-quality results every time. With such an advanced mechanical structure, the ccd laser cutting machine is a versatile tool for various applications.

The laser system comes equipped with advanced safety features to protect the laser tube from potential damage. With both automatic smoke detection and water cooling protection, it provides users with extra peace of mind. If the water cooling mechanism fails, the laser tube is programmed to shut down automatically to prevent further damage, keeping the equipment safe and running efficiently. This reliable function helps to increase the lifespan of the laser tube while preserving its performance levels.

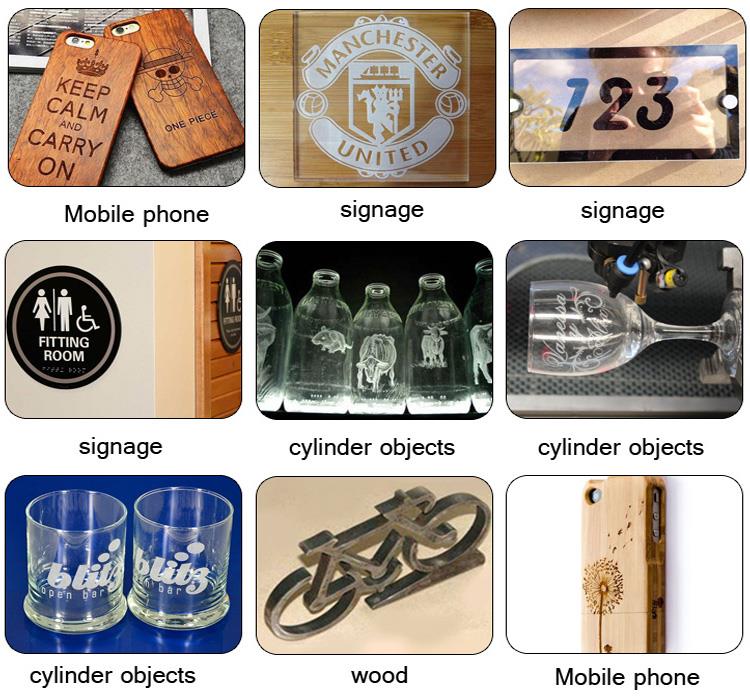

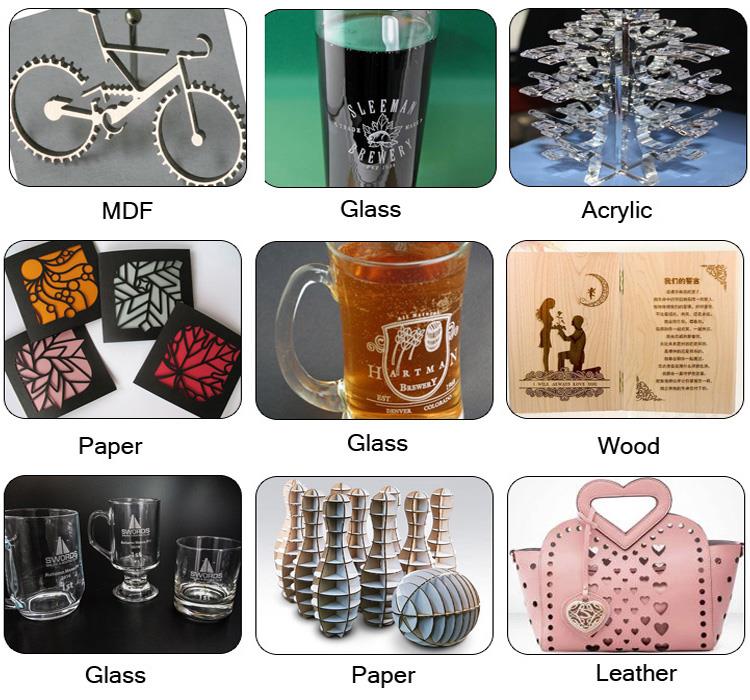

The following materials can be utilized: wood, acrylic, leather, paper, cloth, plastic, rubber, epoxy, tile, bamboo, shell, ABS board. Please rearrange the provided information to generate an alternative content, while ensuring it still remains accurate. It is important to note that this content will be generated using a different approach than that of ChapGPT.

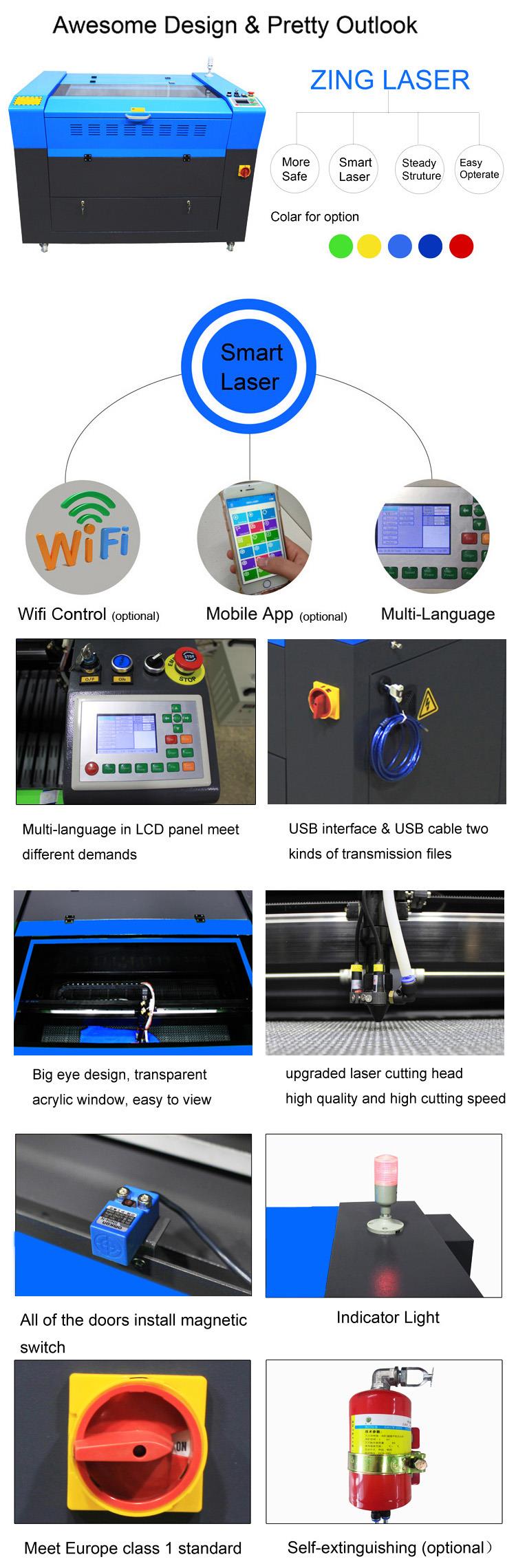

Product Features of ccd laser cutting machine: |

The ccd laser cutting machine series is highly versatile and finds extensive applications in the cutting of diverse types of labels, plaques and trademarks.

By leveraging advanced recognition technology, our cutting-edge solution can seamlessly track and identify the cutting line or key feature points based on chromatic aberration at the edges. This enables automated positioning and precise cutting or punching, eliminating the need for manual alignment in laser cutting processes. With this innovative approach, we offer a complete resolution to the longstanding challenge of human involvement in alignment tasks.

The integration of laser technology, automation technology and artificial vision intelligent technology has led to the development of an automatic camera positioning and recognition system. By seamlessly combining these technologies, this system delivers powerful production and processing capabilities and greatly enhances production efficiency. This state-of-the-art system marks a harmonious fusion of cutting-edge technologies and is set to revolutionize the manufacturing industry. Employing this system in your production processes is guaranteed to enhance your operation's efficiency and performance.

4. Service of JD laser engraving cutting machine:

1. Guarantee for 2 years.

2. Maintenance for whole life.

3. We will provide the consumable parts at an agency price.

4. 24 hours online service, free technical support.

5. Machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, pls kindly tell me.

6.We have manual instruction and CD (Guiding Videos) for software Installation, operation and machine's using and maintenance

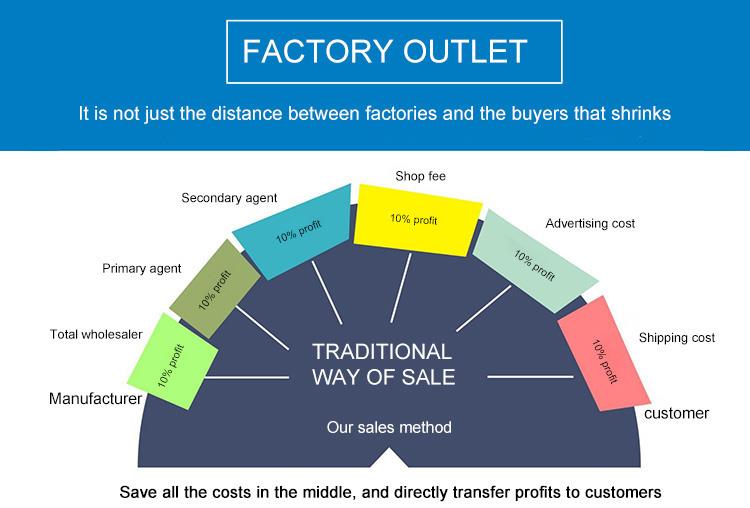

7. Company Information

· Founded in 2002.

· Has developed to a Large-scale International Manufacturing company.

· More Accuracy,More Automatically and Higher Quality Products with Intimate After-sales Service

· Jindiao Be The Leader Of Laser Industry

· Earn the Best Reputation and World-wide Trusted Customers.

· Jindiao laser machines cover all Chinese market and also very popular in America,West Europe,South Asian,East Asian etc. More Than 150 Countries

6. FAQ of laser engraving cutting machine:

Q1: I knew nothing about this machine, what kind of machine i should choose? Very easy to choose. Just tell us what you want to do by using CNC laser machine, then let us give you perfect solutions and suggestions.Q2: When I got this machine, but I don’t know how to use it. What should I do? We will send video and English manual with the machine. If you still have some doubts, we can talk by telephone or skype and e-mail.Q3: If some problems happen to this machine during warranty period, what should I do? We will supply free parts during machine warranty period if machine have some problems. While we also supply free life long after-sales service. So any doubts, just let us know, we will give you solutions. Q4: Before sending me an inquiry on our cnc laser, it is better for you to provide me the following information 1)Your metal or non-metal material size. Because in our factory, we have different models according to working area. 2)Your materials. Metal/Acrylic/plywood/MDF? 3)You want to engrave or cut?

If cut, could you tell me your cutting thickness? Because different cutting thickness need different laser tube power and laser power supplier.

Color is optional and can be customized

Please contact us if you have other special requirements

Send Inquiry

You Might Also Like