wood cutting laser machine

With its wide processing range and generous working width, the wood cutting laser machine is a versatile tool. Its automatic lifting work platform design makes it user-friendly and capable of handling various types of web materials. This design also ensures the optimal focusing and processing of...

Description

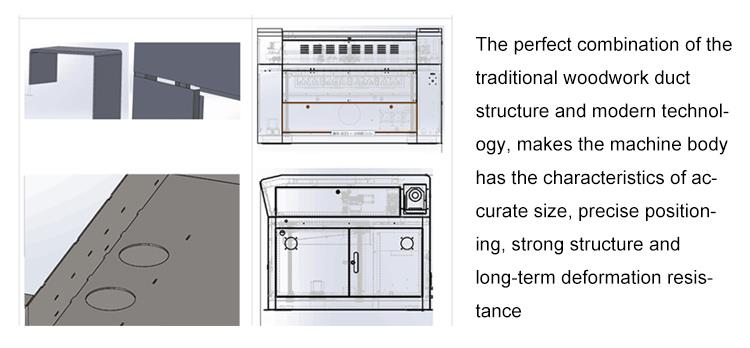

With its wide processing range and generous working width, the wood cutting laser machine is a versatile tool. Its automatic lifting work platform design makes it user-friendly and capable of handling various types of web materials. This design also ensures the optimal focusing and processing of materials with different thicknesses, resulting in impressive outcomes. Additionally, when paired with a spinning device, it can delicately engrave cylindrical materials like bamboo and wood, expanding its functionality.

Technical Parameter of laser cutting machine wood: |

Product model | Z6040 | Z9060 | Z1390 |

Max working area(mm) | 600x400 | 900x600 | 1300x900 |

Laser power | 60W/80W/100W/120W/150W/180W | ||

Laser Types | Hermetic And Detached CO2 Laser Tube | ||

Engraving speed(mm/min) | 0-75,000 | ||

Cutting speed(mm/min) | 0-40,000 | ||

Minimum letter | English 1 x 1mm | ||

Location precision | ≤0.01mm | ||

Resetting positioning accuracy | 0.01mm | ||

Driving system | Stepper | ||

Software | Lasercut 5.3 or RDworks V8 | ||

360°slope engrave | Yes | ||

Power supply | AC 220V(or 110V)/50~60HZ | ||

Operating temperature | 0 - 45℃ | ||

Operating humidity | 5 - 95% | ||

Laser output control | 1-100% control panel and software setting | ||

Highest scanning precision | 50-1000DPI | ||

Compatible software | CorelDraw, AutoCAD, Photoshop | ||

Auxiliary Devices | Exhaust fan and Exhaust pipe | ||

Cooling mode | Water-cooling and protection system | ||

Operating system | Window 98/ME/2000/XP/VISTA/2007 | ||

Graphic format supported | TIANDAO,。BMP、CIF、JPEG、TGA、TIFF、PLT、AI、DXF、DST、DWGCDR。,。TIANDAO,,。,。TIANDAO,,。 | ||

Accessories | The base, wheel, water pump, air pump, and exhaust fan are all important components in various systems. The water pump is responsible for moving water through pipes and keeping processes functioning properly. The air pump is used to provide air to different applications, such as in aquariums and aerating soil. Exhaust fans are needed to remove harmful gases and fumes from an area. The base provides a solid foundation for equipment, while wheels allow for mobility when necessary. Each of these components has its unique purpose, and when combined, they are essential for completing tasks efficiently and effectively. | ||

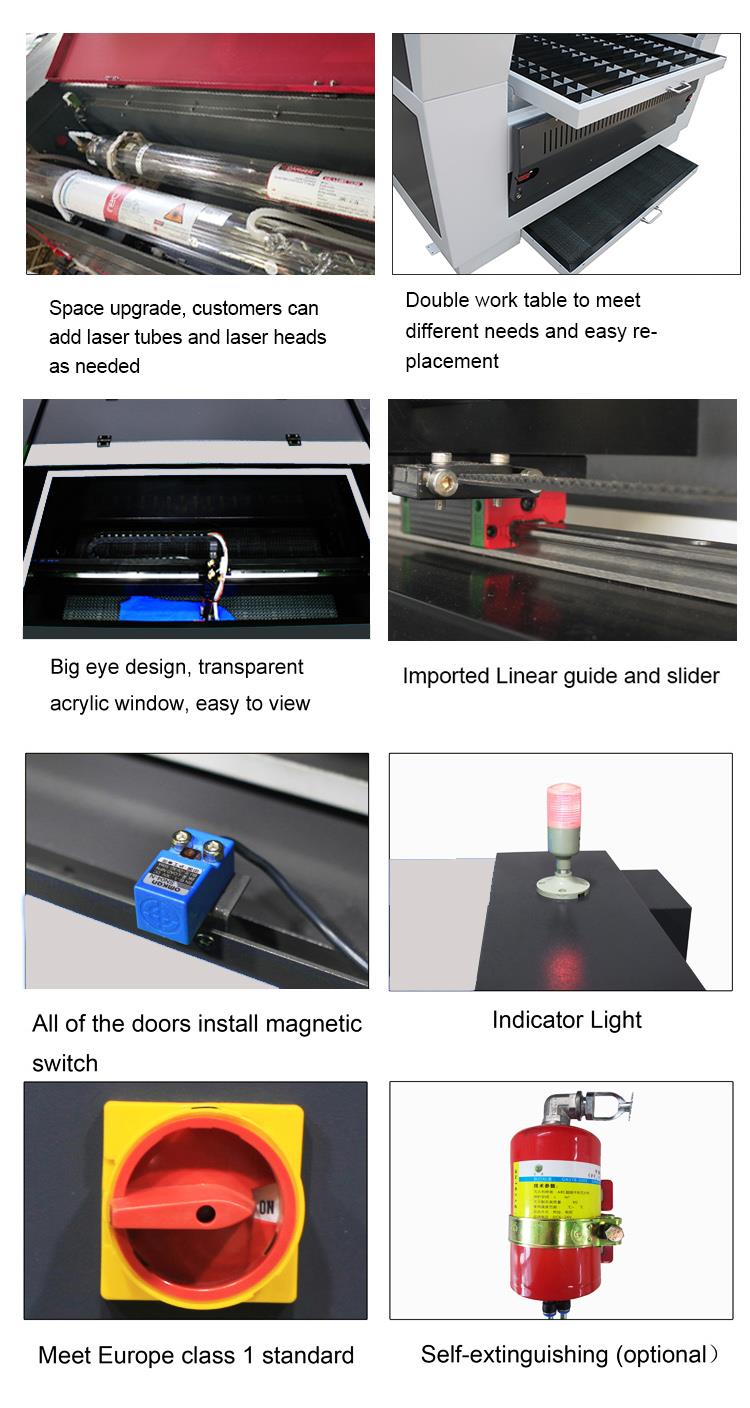

Product Features of wood laser cutter: |

When it comes to wood cutting laser machines, the basic principle is quite similar to that of a regular laser cutting machine. However, instead of cutting through the material entirely, the laser beam is converted into thermal energy which causes thermal breakdown and charring of the wood. This process removes certain portions of the wood material instantly, allowing for precision cutting and engraving.

Unlike traditional machining methods, laser cutting and engraving offer a non-contact processing option. This means that there is no tool wear, no tool change, and no noise pollution during operation. Additionally, laser engraving requires far less energy than laser cutting since it does not involve cutting through the workpiece. This results in a cleaner process with no wood chip contamination.

Overall, whether you're looking to cut intricate designs or engrave patterns onto wood material, a wood cutting laser machine can provide a highly precise and efficient solution.

Send Inquiry

You Might Also Like