Small Wood Laser Cutter Carving Machine

As the cutting and engraving process becomes more intricate, older methods like manual processing and mechanical processing are being hindered by equipment and technology limitations. This, in turn, leads to lower precision levels in processed objects, ultimately impacting product quality and...

Description

Technical Parameter |

Product model | Z6040 | Z9060 |

Max working area(mm) | 600x400 | 900x600 |

Laser power | 60W/80W/100W/120W/150W/180W | |

Laser Types | Hermetic And Detached CO2 Laser Tube | |

Engraving speed(mm/min) | 0-75,000 | |

Cutting speed(mm/min) | 0-40,000 | |

Minimum letter | English 1 x 1mm | |

Location precision | ≤0.01mm | |

Resetting positioning accuracy | 0.01mm | |

Driving system | Stepper | |

Software | Lasercut 5.3 or RDworks V8 | |

360°slope engrave | Yes | |

Power supply | AC 220V(or 110V)/50~60HZ | |

Operating temperature | 0 - 45℃ | |

Operating humidity | 5 - 95% | |

Laser output control | 1-100% control panel and software setting | |

Highest scanning precision | 50-1000DPI | |

Compatible software | CorelDraw, AutoCAD, Photoshop | |

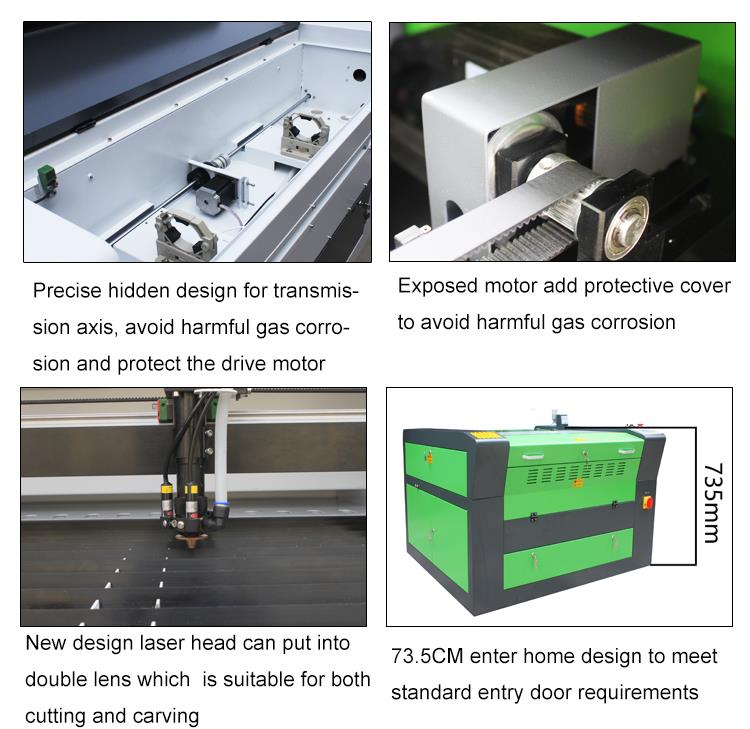

Product Features |

As the cutting and engraving process becomes more intricate, older methods like manual processing and mechanical processing are being hindered by equipment and technology limitations. This, in turn, leads to lower precision levels in processed objects, ultimately impacting product quality and economic gains.

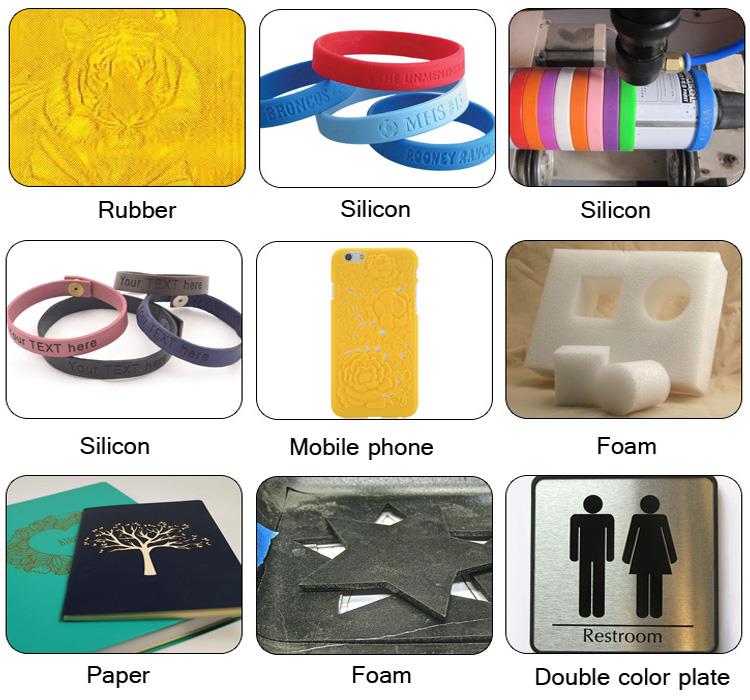

After years of developing laser equipment, a Small Wood Laser Cutter Carving Machine has been produced utilizing the high energy density and functionality of lasers. It stands out for its ability to process various materials with precision and efficiency while producing smooth edges without burrs or dust. This machine is also incredibly fast, produces minimal waste, and operates quietly, making it an excellent choice for a range of industries. Whether as a new addition or replacement, the Small Wood Laser Cutter Carving Machine is an ideal investment.

Precautions

Ensure that the automatic measuring rod is tightened when using the auto focus, as failing to do so may result in the laser covering the working surface. It is crucial to pay close attention to this detail to avoid any potential mishaps.

While the laser engraving machine is operational, it is strictly prohibited to ever open the cover.

To ensure a safe work environment, it's important to open the smoke exhaust and activate the smoke removal equipment while processing. This will help to effectively eliminate the smoke and prevent potential health hazards.

When working with wood or paper, it is crucial to be mindful of the processing speed to prevent any potential risks of fire. Therefore, it is important to proceed with caution and take necessary safety precautions to avoid any accidents in the workplace.

During irregular processing, the first user conducts a red light positioning to ensure accuracy and precision.

Send Inquiry

You Might Also Like